- Gaea

- China

- 10 days

- 3000pcs/ctn

Liaoning Gaea Rock Split Machinery Technology Co.,Ltd is a manufacturer which have rich experience in rock splitting technical and export quarrying and drilling tools to all over the world.We provide scheme design,device manufacture and drilling tools sell. We devote to research,scheme design, products manufacture and sell the steady, trustable and cost-efficient rock splitting system solutions.

Product including:

Rock blasting system;

Rock demolition tools;

Jack hammer;

Drilling rods;

DTH hammer;

Shank adapter;

Button bits;

DTH bits;

Tricone bits;

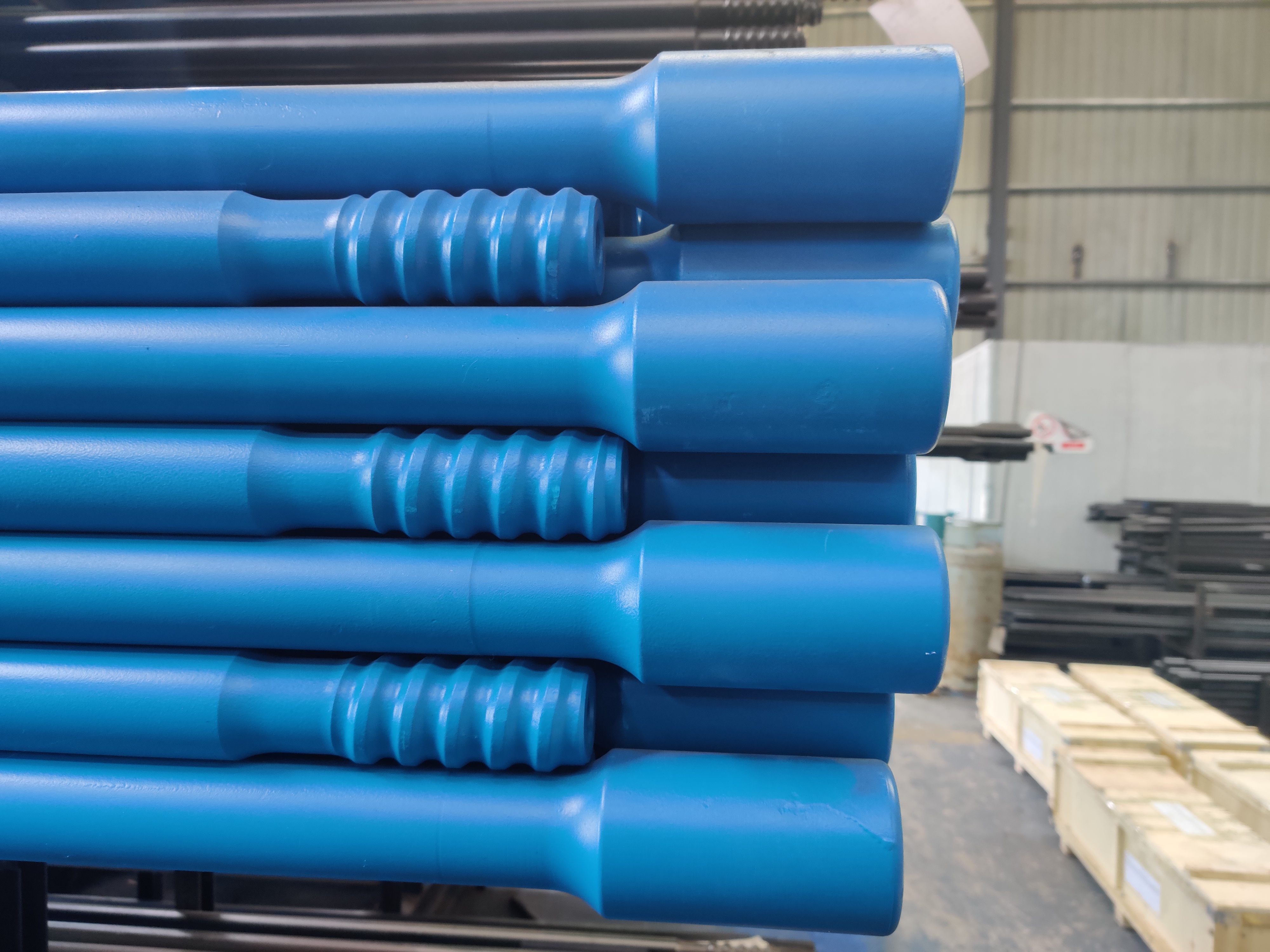

T38 extension rod rock drilling rod 3050mm 3660mm Extension Drill Rod drill pipe top hammer

Related reports:

What material is the rock drill rod made of? How heavy is one;

What are the effects of incorrect use of drill rods;

Loading and unloading method of drill pipe;

Our company, Liaoning Gaea, takes pride in offering top-quality T38 thread drilling rods. As a leading product in our portfolio, our T38 thread drilling rods have received widespread acclaim and have been exported to numerous countries worldwide. We are dedicated to providing exceptional products that meet the needs of mining and quarrying operations.

The T38 thread drilling rod, also known as the T38 extension rod or T38 drilling rod, is designed to deliver excellent performance and durability in demanding drilling applications. With its sturdy construction and reliable threading, this drilling rod ensures seamless connection and optimal drilling efficiency.

To ensure the proper usage of the T38 thread drilling rod and prevent any premature failures, it is essential to consider the following points:

1.Confirm a good match between the thread of the drilling rod and the coupling sleeve. Ideally, both should be provided by the same manufacturer. Matching the specifications, such as the diameter of the drilling rod, is crucial. Larger specifications are suitable for high-impact power rock drills, while smaller specifications are compatible with low-impact power rock drills. Mismatched specifications may lead to early failures.

2.Regularly inspect the condition of the thread for any significant wear. If substantial wear is observed, it is advisable to replace the drilling rod to avoid potential fractures and mitigate further losses.

3.Check for any bending or deformations in the drilling rod. If severe bending is noticed, it is necessary to discontinue its use (unless the rod is straightened properly) to ensure safe operations.

4.Maintain stability during the drilling process and adjust the working pressure parameters accordingly to prevent unexpected damage.

5.Adapt the working parameters promptly based on the rock conditions and the condition of the drilling bit. Due to the disparity in quality between domestic and top-tier international drilling rods, it is important to adjust the working parameters accordingly. When compensating for drill cuttings, timely replacement of the drilling bit enhances the working efficiency of the drilling rod. In softer rock formations, lowering the impact pressure and advancing force extends the lifespan of the drilling rod.

6.Select the appropriate working parameters for the rock drilling machine. For machines with adjustable parameters such as impact pressure, impact power, impact frequency, advance force, and rotational speed, it is crucial to match higher impact power with larger-sized drilling rods and lower impact power with smaller-sized rods. Failure to do so may lead to premature fractures of the drilling rods.

7.We recommend using our quick-change drilling rods (MF rods) for improved drilling efficiency.

8.In the event of early failures (with minimal thread wear), promptly notify our company in writing so that we can address the situation in a timely manner.

At Liaoning Gaea, we are committed to delivering high-quality T38 thread drilling rods that meet the rigorous demands of mining and quarrying operations. Contact us today to learn more about our exceptional products and services.

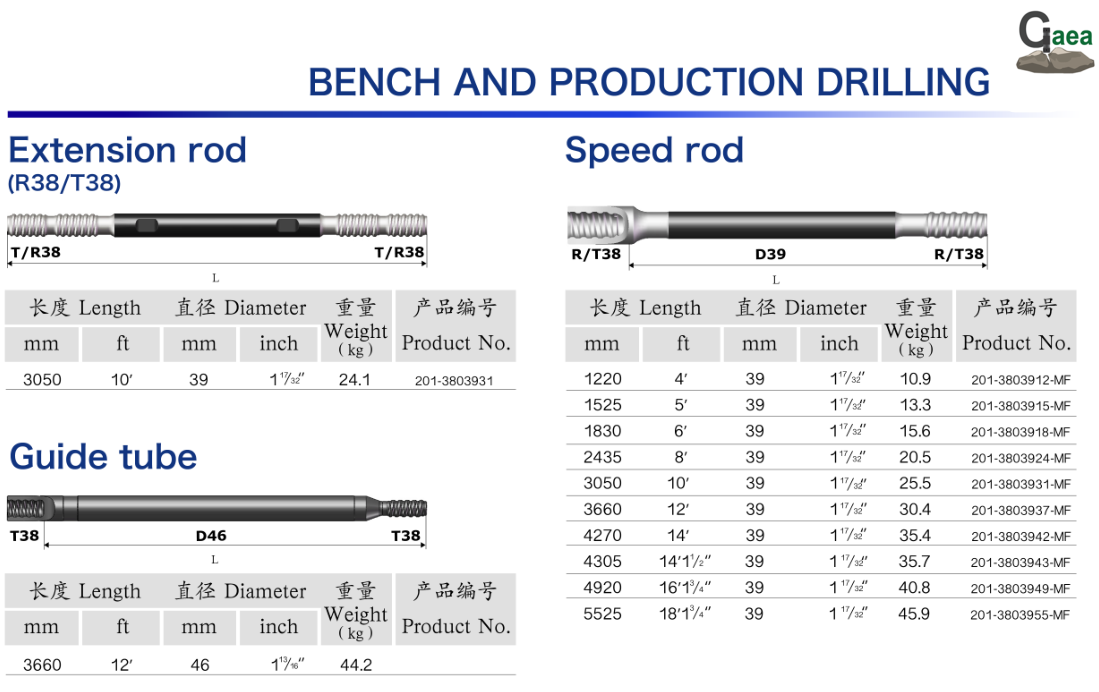

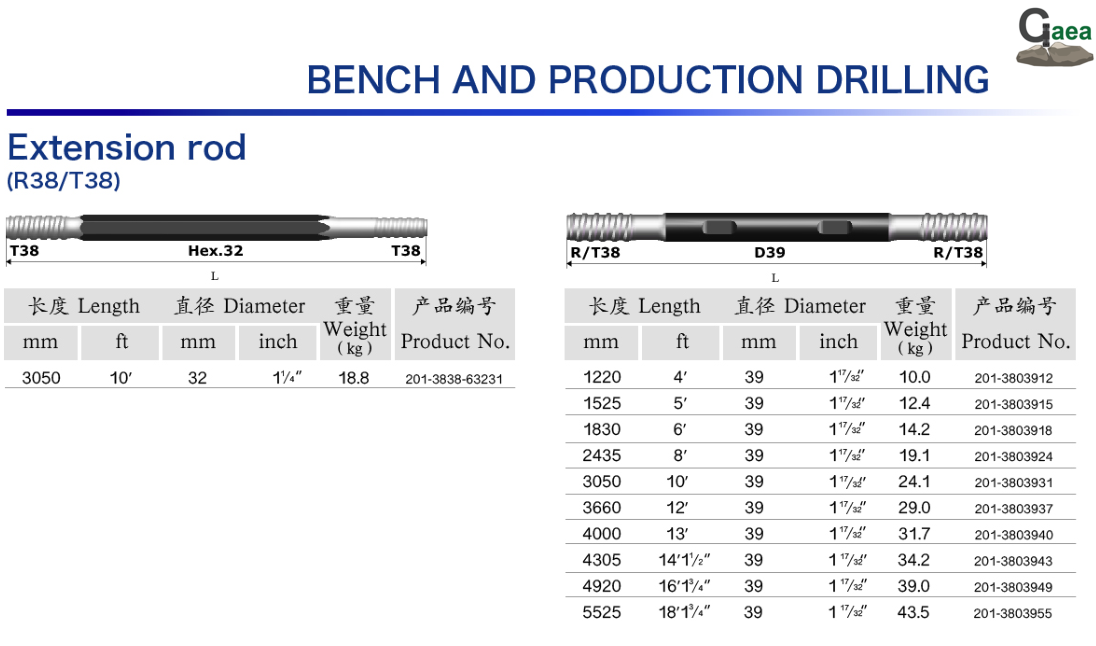

T38 extension rod specification:

1. The characteristics of trenchless engineering

Trenchless engineering is a high-risk engineering project. The quality of drill pipes(extension rod) and the correct selection and use of specifications are important factors to ensure the smooth completion of the project, but it is not the only factor. Pre-construction preparations, such as rationality of design, site investigation, geology, surface analysis, quality of construction personnel, construction methods, performance and reliability of drilling rigs, mud ratio and application, configuration of construction equipment, etc., are all related to non- An important factor in the success or failure of an excavation project.

2. Matters needing attention in the use of drill pipes(drill rod/extension rod)

1. According to the drilling rig's torque, push-pull force, and the minimum allowable radius of curvature, select a drill rod of appropriate specifications and models.

2. Avoid connecting large-diameter drill pipes with small-diameter drill pipes during construction, (ie, mixed use of large and small drill pipes) to prevent small drill pipes from being broken or deformed due to insufficient strength.

3. Be careful not to clamp the female buckle part of the female connector when clamping the drill pipe(extension rod) with a vise to prevent the female buckle from being clamped and deformed.

4. Note that when installing the drill pipe(extension rod), the make-up pre-tightening force should be controlled within 15 MPa to prevent the difficulty of unloading due to excessive pressure. Avoid using fire-bake joints to reduce the mechanical properties of the joints, (especially the female joints) affect the service life. Without pre-tightening, the threaded connection swings, and the crest becomes sharp when the threads are ground each other, and ridges are formed on the side, which causes the thread to damage the goods and cause the phenomenon of sticking. Without pre-tightening, the step of the female buckle is not compressed, which can cause the thread root of the male connector to break due to fatigue. Under the action of the high-pressure liquid flow, the female connector is pierced, causing puncture and corrosion, which can easily lead to longitudinal cracks of the female connector.

5. Note that before attaching the drill pipe, clean the male and female buckles, and apply threaded oil (the threaded oil cannot be replaced by other waste oil or low-quality press oil) to prevent premature wear or damage .

6. Pay attention to cleaning the water channel hole before installing the drill pipe(extension rod) to prevent debris from blocking the channel and causing the mud system to hold back pressure.

7. Be careful not to forcibly buckle up. When buckling, the male buckle should not impact the shoulder and thread of the female buckle, and ensure that the male and female joints are aligned. Ensure the coaxiality between the shackle of the drilling rig and the main shaft of the power head.

8. Pay attention to check the wear of each part of the drill pipe. If there is abnormal wear, you should find out the cause in time:

1) Determine whether the sharp hard material in the hole scratches the drill pipe(extension rod)

2) Please use caution when the scratch marks on the body of the drill rod are about 1mm deep and have a spiral shape more than one circle. Prevent the drill rod from being broken during construction, causing greater losses.

9. Attention should be paid to the short-circuit buckle type damage of the drill collar (cross buckle, random buckle, serious wear, etc.), it should be replaced in time to avoid damage to the drill pipe(extension rod) thread.

10. Pay attention to hoisting, and avoid damaging the male buckle by impact when transporting the drill pipe.

11. Pay attention to avoid mixing drill rods of different buckle types. Do not mix drill rods(extension rod) even if they are not produced by the same manufacturer (because of the differences in technical parameters, processing methods, props, and mechanical equipment of the drill rods manufactured by each manufacturer, the tolerances of the drill rods processed , Tight distance, etc. must be different); the old and new are too different, and the drill pipes with too much difference in the degree of wear should not be mixed to avoid construction hazards.

12. It is found that the drill pipe buckle type has local small-scale damage (about 1-2 buckles, buckle length 10mm), and it should be repaired in time before use.

13. Use qualified zinc-based rib grease. Butter is not suitable for use as thread oil. Insufficient thread grease will cause high points of damage to the shoulder of the joint, which will easily "loose" the threaded connection and cause the thread to be damaged. Do not use thread grease or use unqualified thread grease, which will cause the surface of the thread to stick and cause the phenomenon of sticking.

Three, the possible failure of the drill pipe in use

1. The drill pipe breaks along the male and female buckle thread

2. Broken drill pipe body

3. Fracture or open welding of friction welding joint

4. The drill rod body is bent or twisted

5. Drill pipe female buckle end face expansion

6. Deformation of the end face of the drill pipe female button

7. Drill pipe buckle type damage

8. The surface of the drill pipe male and female joints is seriously damaged

4. Reasons and treatment methods of drill pipe failure

1. The drill pipe is broken along the male and female buckle thread

1) The torque of the drilling rig exceeds the torque that the inclination of the drill pipe can bear

2) The radius of curvature of the construction hole exceeds the minimum radius of curvature of the drill pipe

3) When reaming (especially when expanding the hole) or drilling a pilot hole for a long distance, the drill suddenly hits a hard object and produces a strong impact. Cause the torque to increase suddenly, causing the drill pipe to break or twist off.

4) The operator should reasonably control the rotation speed and propulsion force when operating the rig to avoid such situations.

2. The drill pipe body is broken

1) The torque of the drilling rig exceeds the torque that the inclination of the drill pipe can bear

2) The radius of curvature of the construction hole exceeds the minimum radius of curvature of the drill pipe

3) When expanding the hole (especially when expanding the hole) or drilling a pilot hole for a long distance, the drill suddenly hits a hard object and produces a strong impact. Cause the torque to increase suddenly, causing the drill pipe to break or twist off.

4) The material and thickness of the drill rod body do not meet the technical specifications.

5) The surface of the drill pipe body is severely scratched (more than 1mm in depth and in a spiral shape)

6) The drill pipe has been used for too long, and the surface damage is too much, which is close to or exceeds the fatigue life.

3. The friction welding joint of the drill pipe is cracked or broken

1) Welding quality problems

2) The problems in Article 1 and Article 2 shall be handled in the same way.

4. Bent or twisted drill rod body

1) The thrust is too large or too strong when drilling the pilot hole.

2) The radius of curvature of the pilot hole during construction is too small

5. End face expansion of drill pipe female button

1) Different buckle types, different manufacturers, and new and old drill pipes are mixed, causing the tight distance to exceed the standard when the drill pipe is connected, and the female buckle expands the buckle.

2) The buckle type of the protection pup joint of the power head of the drilling rig does not match the buckle type of the drill pipe or the wear is too serious, and the tight distance tolerance is large.

3) The lengths of the male and female ports are not properly matched, and the main and auxiliary step surfaces of the joint cannot be double-topped.

4) The radius of curvature of the hole exceeds the allowable radius of curvature of the drill pipe, causing the female button to expand

6. Deformation of the end face of the drill pipe female button

1) The vise slip is clamped on the female part

2) When the buckle cannot be removed due to too much torque, hit it with a sledgehammer or burn it with fire to cause deformation.

7. Drill pipe buckle type damage

1) Qualified threaded oil is not used.

2) The thread surface is not cleaned

8. The surface of the drill pipe male and female joints is seriously damaged

1) The hardness of the vise slips is too large, and it is injured by the vise slips.

2) Joint heat treatment, nitriding hardness problem or material problem.

3) The joint was hit by a sledgehammer or fired due to difficulty in unfastening.

Please avoid or replace as much as possible.

If you need T38 thread button bits,pls check this link:

If you need T38 shank adapter,pls check this link: