Application of Air-Cooling and Cuttings-Discharge PDC Bit Technology

At present, in gas-drainage borehole drilling for coal mines, bit cooling is typically achieved by water injection or air injection, depending on geological conditions and process requirements. The goal is to prevent excessive heat buildup caused by high-speed rotational friction, thereby avoiding wear, chipping, or loss of PDC cutters.

During water-injection drilling, fluctuations in injection volume and differences in formation softness often lead to hole blockage as water-sensitive rock expands. In addition, water-based drilling commonly shows poor cuttings return in negative-angle and vertical boreholes, which can easily trigger sticking incidents. If drilling is interrupted, water-mixed cuttings may consolidate and lock the drill string. For these reasons, water-injection drilling is not suitable for PDC bit operations in many scenarios.

With conventional air drilling, pressure air is transmitted through the drill rod bore to the PDC bit. However, due to sealing limitations and long transmission distance, air loss often occurs, reducing cooling performance below expectations. At the same time, large ventilation passages can cause uneven airflow distribution, making efficient cuttings transport difficult.

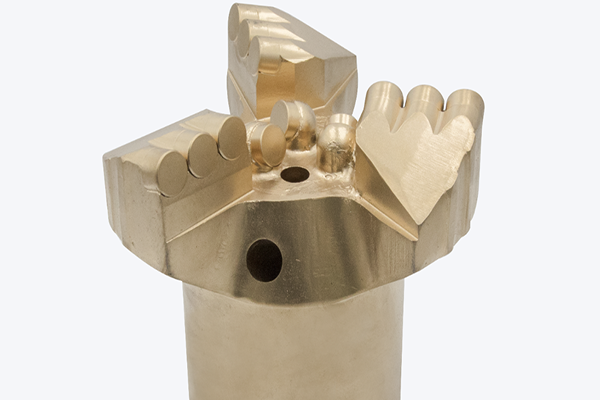

Based on long-term field collaboration with frontline coal-mine users, our company developed a PDC bit for air-driven cuttings removal. Its key feature is an air outlet positioned below the cutter, with an outlet diameter no greater than 2 mm and a specific angular relationship between the outlet and the cutter. During operation, high-pressure air forms a high-velocity jet through the 2 mm nozzle and is directed at the cutter’s cutting edge angle, enabling rapid cooling.

This air-cooling, cuttings-discharge PDC bit mainly consists of a crown-structure body, air-jet nozzle assembly, and PDC cutters. The crown top uses a multi-blade segmented wing design, with cutters arranged at optimized blade positions. High-pressure air exits below the cutters to provide direct air cooling, effectively preventing bit burning and excessive wear caused by insufficient airflow or air velocity. In addition, high-pressure air cooling can significantly reduce sticking problems during fault-zone drilling, and its operational efficiency is typically 4–5 times that of water-cooling methods.

In summary, this air-cooling and cuttings-discharge PDC bit effectively addresses thermally induced cutter damage during drilling. By combining strong air pressure with improved cuttings removal, it also increases drilling efficiency while supporting energy-saving and consumption-reduction objectives.