From Soft to Hard Rock: Choosing Round Teeth or Pointed Teeth for DTH Drill Bits — It All Comes Down to the Rock

In down-the-hole (DTH) drilling, rock type is the decisive factor when selecting a bit tooth profile. Differences in hardness and compressive strength directly affect the crushing efficiency, wear rate, and operating cost of round (rounded) teeth versus pointed teeth. Only by matching tooth geometry precisely to rock properties can drilling be efficient and economical; the wrong choice leads to poor penetration rates and rapid bit wear.

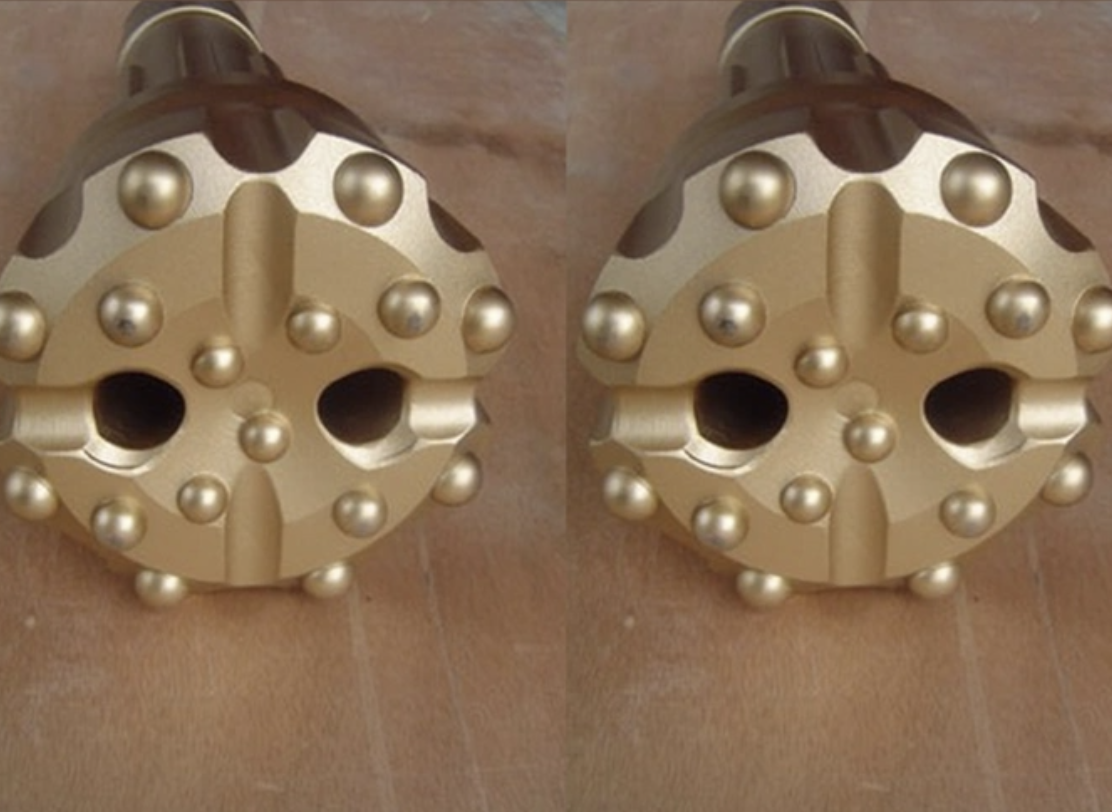

Soft rock: round teeth are ideal — “gentle crushing” for efficient drilling Soft rocks are characterized by low hardness and low compressive strength (typically < 30 MPa), such as shale, claystone, marl, and friable sandstone. These rocks break without aggressive puncturing; the round-tooth crushing mechanism of “compression + grinding” matches this behavior and is the preferred choice for soft-rock drilling.

Why round teeth suit soft rock Soft rocks are relatively loose and weak in compression. The round-tooth design provides surface contact that creates a larger contact area during impact, distributing force more evenly across the rock surface. This compression causes plastic deformation and fragmentation — a process similar to a road roller compacting material — so heavy, localized impacts are unnecessary. That both saves energy and minimizes excessive destruction of the rock structure. During rotation, round teeth also grind previously broken cuttings into finer particles, which are easier to evacuate with flushing media and less likely to clog the hole. Uniform fragmentation also helps maintain borehole stability, avoiding irregular hole profiles and wall collapse.

Problems when pointed teeth are used in soft rock Pointed teeth focus force on a very small area (point contact), which over-fragments soft rock into fine powder. This wastes energy (power is not converted into effective penetration) and can lead to clogging of the flush and cuttings channels when fine powder adheres to channel walls, reducing drilling efficiency. The pointed tips in a low-resistance environment can deform (bend or blunt), shortening bit life and increasing replacement costs.

Hard rock: pointed teeth are preferred — “forceful penetration” to overcome high strength Hard rocks have high hardness and high compressive strength (typically > 60 MPa), such as granite, quartzite, basalt, and diabase. These dense, strong rocks cannot be broken effectively by compression alone; they require the puncture-and-splitting action of pointed teeth for efficient penetration. Therefore pointed teeth are the clear choice for hard-rock drilling.

Why pointed teeth suit hard rock Dense hard rock has strong internal bonding; surface-contact compression alone cannot break it. Pointed teeth concentrate impact force on a small tip area (contact area only about 1/5–1/10 that of round teeth), producing much higher local pressure (several times that of round teeth). This concentrated pressure punctures the rock surface and initiates cracks. With continued rotation and impact, these initial cracks grow, link up, and propagate along fracture planes, effectively splitting the rock — like a wedge splitting wood. This directly attacks the rock’s internal structure and rapidly increases penetration rates. In granite drilling, for example, penetration with pointed teeth can be 2–3 times faster than with round teeth and avoids the “grind-without-penetration” problem that round teeth exhibit on hard surfaces.

Problems when round teeth are used in hard rock Round teeth distribute force over a larger area, preventing the high local pressure needed to fracture hard rock. Impacts produce only surface scoring or abrasion rather than true breakage, so penetration rates may be only 1/5–1/10 of those achieved with pointed teeth, wasting energy in idle rotation. The severe friction against high-hardness rock rapidly abrades round teeth (often requiring replacement after 1–2 hours), whereas pointed teeth under the same conditions may last 4–6 hours. Frequent bit changes increase downtime and total cost.

Medium-hard rock: decide based on detailed lithology — be flexible or use hybrid designs Between pure soft and pure hard rock lies medium-hard rock (compressive strength 30–60 MPa), such as dense sandstones, crystalline limestones, and some gneisses. Tooth selection for these rocks must consider detailed lithology (e.g., presence of quartz grains, heterogeneity). In many cases a mixed or hybrid tooth pattern (round + pointed) is appropriate.

Criteria for choosing teeth in medium-hard rock

If the medium-hard rock is uniform and lacks hard interbeds (e.g., homogeneous dense sandstone), prefer “reinforced round teeth” (higher hardness and optimized contact arc) to enhance compression-based breakage; round teeth can deliver balanced efficiency and reduced wear compared with pointed teeth.

If the medium-hard rock contains quartz particles or local hard spots (e.g., crystalline limestone or sandstone with flint layers), choose “short, stout pointed teeth” (thicker, harder tips) to pierce local hard points and avoid rapid local wear of round teeth.

If lithology is layered (e.g., soft layers above hard layers), use a mixed-tooth bit design — round teeth on the outer ring and pointed teeth on the inner ring — to handle different layers without frequent bit changes.

Core principle for medium-hard rock Avoid an absolute “soft vs. hard” mindset; the rule is to address the dominant rock characteristic. If the overall lithology trends softer with only local hard spots, prioritize round teeth with pointed teeth as backup. If overall lithology trends harder with local soft seams, prioritize pointed teeth with round teeth as backup. Validate the choice by trial drilling (e.g., drill 10–20 minutes, then inspect tooth wear and penetration) and adjust to optimize performance.

Summary: three core factors that determine tooth selection The influence of rock type on choosing round vs. pointed teeth boils down to three core factors: hardness, compressive strength, and structural uniformity. The selection logic can be summarized as:

Hardness + compressive strength: low hardness/low compressive strength → choose round teeth; high hardness/high compressive strength → choose pointed teeth.

Structural uniformity: homogeneous lithology (no interbeds or hard spots) → a single tooth profile matching the dominant rock is acceptable; heterogeneous lithology (with interbeds or hard spots) → require flexible pairing or a hybrid tooth pattern.

Matching operational goals: if you seek “high efficiency + long life” → select the tooth geometry precisely for the rock; if you need “broad adaptability to multiple lithologies” → consider hybrid tooth designs or replaceable cutter heads.

Rock type is the conductor of tooth selection for DTH bits. Only by understanding the rock’s characteristics can you exploit the strengths of round and pointed teeth and achieve maximum drilling efficiency with minimum cost.