New type of rotary digging teeth solve the problem of short service life

Related products Link:

In order to solve the drawback that the service life of the rotary digging tooth is greatly shortened, the technical problem to be solved by the present invention is to provide a rotary digging tooth on the rotary mining machine, which has a longer service life. In order to solve the above technical problems, the technical solution adopted in the present invention is a rotary excavating tooth of a rotary excavator. The rotating digging teeth are provided with mounting holes. Carbide rods consist of a root and a working part. The root of the cemented carbide rod is inserted into the mounting hole, and it is characterized in that the mounting hole and the root of the cemented carbide rod are assembled through thermal interference fit.

The interference ratio can be determined according to the material properties and the dimensional requirements of the holding force. In addition, the interference ratio of the interference fit is the maximum outer diameter of the carbide rod: the inner diameter of the mounting hole = 1.005:1. That is, the maximum outer diameter of the carbide rod is five-fifths larger than the inner diameter of the mounting hole.

The beneficial effects of the rotary digging teeth are that the connection can be completed without brazing during the assembly process, the rotary digging teeth do not undergo high-temperature annealing to reach the melting point of copper, and the hardness and wear resistance will not be damaged due to assembly. The fit is tight and there is no weak area, which is beneficial to improve the retention force of the inner wall of the mounting hole to the outer wall of the root of the shaft, and the cemented carbide rod will not fall off under harsh working conditions.

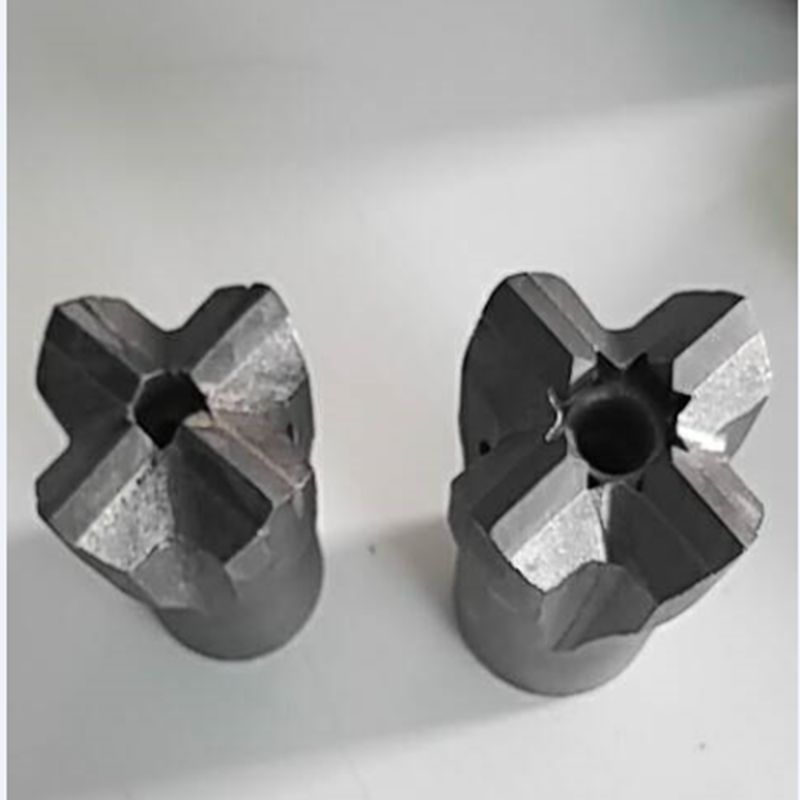

Preferably, the grooves are distributed uniformly on the side surface of the root of the cemented carbide rod, and the grooves penetrate axially through the side wall of the root. During the process of pressing the root of the cemented carbide rod into the mounting hole, it is advantageous that the air in the hole is expelled along the groove to ensure smooth placement of the assembly. The cemented carbide rod of this structure is beneficial to improve the inner wall of the mounting hole. The holding force of the non-grooved portion of the outer wall of the stem base prevents rotation of the base relative to the mounting hole. Therefore, the cemented carbide rod can be prevented from falling off, and the service life of the digging teeth can be effectively prolonged. Further preferably, the cross-section of the cemented carbide rod is quincunx-shaped. Preferably, the number of grooves is 3 to 5.

Advantageously, a washer is arranged between the end face of the tooth root of the turning tooth and the end face of the inner cavity of the turning tooth holder. In this installation structure, there is no direct contact between the end face of the rotary digging tooth root and the end face of the inner cavity of the rotary digging tooth holder, but there is a movable part, so that there is a movable adjustment space. When a paper jam occurs, it is beneficial to maintain the spin function of the teeth, thereby prolonging the service life of the rotary digging teeth.