Teach you how to distinguish between drilling rigs, drilling rigs and rigs

1.The necessity of product name discrimination

In the earthwork, tunnel engineering and mining machinery industries, names such as "drilling rig", "drilling rig" and "trolley" often appear. For down-the-hole equipment, most people call it "drilling rig" and some people call it "drilling rig"; Hammer-type rock drilling equipment is called "rock drilling rig" by some, "drilling rig" by some, and "drilling rig" by others. There is no unified and standardized name for each type of rock drilling equipment.

The chaotic state of the use of product names is not conducive to the management of social commodity statistics, technical and commercial exchanges, and even more detrimental to search engine terms.

2. Drilling principle

2.1 Principle of percussion drilling

The percussion principle is suitable for the drilling of rocks above medium-hardness. The equipment that adopts the percussion method for drilling includes pneumatic rock drills, hydraulic rock drills, down-the-hole drills, steel rope percussion drills, etc. Impact drilling can be divided into two methods: down-the-hole drilling and top hammer drilling.

2.1.1 Principle of down-the-hole drilling

The principle of down-the-hole percussion drilling is to install the impactor that produces impact on the bottom of the drill pipe and directly impact the drill bit to perform drilling.

2.1.2 The principle of top hammer percussion drilling

The principle of top hammer percussion drilling. Top hammer drilling is a method in which a rock drill that produces an impact is installed on the top of the drill pipe and directly impacts the drill pipe. The impact energy is transferred to the drill bit through a special stem for drilling.

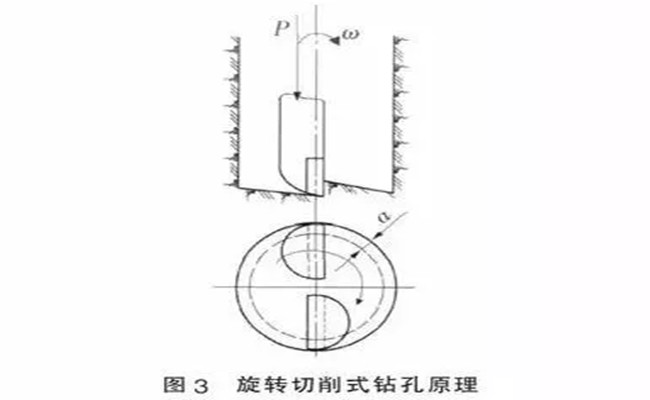

2.2 Principle of cutting drilling

Cutting drilling principle, cutting type principle is suitable for drilling in soil or soft rock. The cutting method drilling equipment includes cutting drilling rigs, rotary drilling rigs, coal power stations, coal bolting rigs, etc. Because the cutting action is mainly produced by rotating torque, it is also called rotary cutting drilling.

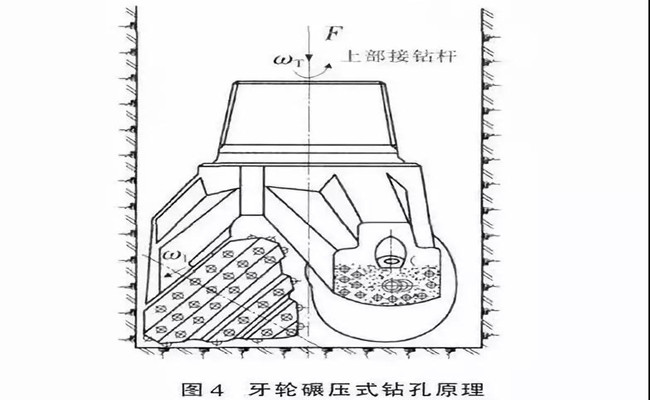

2.3 Principle of Rolling Drilling

The rolling principle is suitable for drilling in rocks below medium-hardness, and the roller cone drilling machine uses the rolling principle to drill holes. The drill rig is connected to the roller cone bit through the drill rod, and pressurizes the drill rod to make the drill bit contact the rock. At the same time, under the rotation of the drill rod, the cone with column teeth on the drill bit is rolled, and the column teeth in contact with the rock transmit vibration impact and pressing force to break the rock. This drilling method combines vibration impact crushing and shearing crushing, so it is called rolling drilling. Because the cone rolls on the rock, it can also be called rolling drilling. Both coal mine boring machines and tunnel boring machines apply the principle of rolling and crushing rocks.

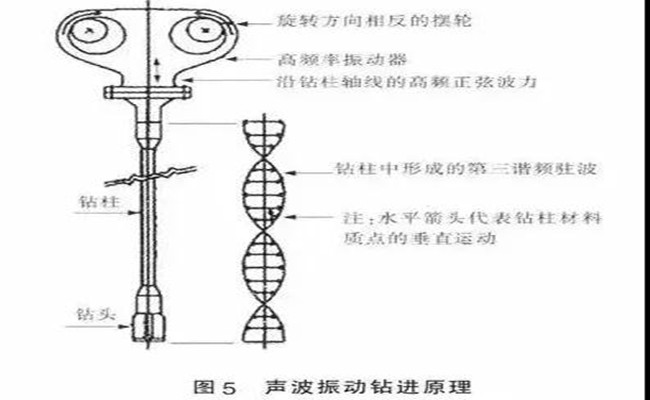

2.4 Principle of Vibratory Drilling

Principle of vibratory drilling, vibratory drilling is suitable for drilling in soil or soft rock. The equipment used for vibrating drilling includes sonic drills and ultrasonic rock drills.

2.5 Combination of multiple principles

Impact, cutting, rolling, and vibration methods are the four basic methods for drilling holes in rock or soil. Actual drilling equipment is generally a combination of several principles. For example, hydraulic rock drills are mainly used for percussion, supplemented by cutting. Sonic drilling is based on vibration as the main action, and the combined effect of vibration, rotary cutting and rolling principles.

3.1 Drilling

Whether it is earthwork, tunnel engineering or mine excavation; whether it is impact type, cutting type or vibration type, as long as it is a drilling operation, it can be called drilling.

3.2 Perforation

In the rock excavation operations of open-pit mines and underground mines, drilling can also be called perforation.

3.3 Rock drilling

Percussion drilling and percussion drilling operations can be called rock drilling. Equipment that uses other drilling principles, such as cutting and vibration drilling operations, cannot be called rock drilling.

Definition of down-the-hole hammer, rock drill and power head

4.1 Definition of down-the-hole impactor

As the name suggests, the device that uses the principle of DTH to drill is called DTH impactor. DTH impactor is referred to as impactor for short, so it is also called DTH hammer. GB/T 6247 defines a down-the-hole impactor as "an appliance installed on the front end of the drill pipe and submerged into the bottom of the hole for rock drilling", which is completely accurate.

4.2 Definition of Rock Drill

A machine that uses the principle of top hammer percussion for drilling is called a rock drill. Rock drills are divided into pneumatic rock drills and hydraulic rock drills; they can also be divided into hand-held rock drills, outrigger rock drills, and rail type rock drills.

GB/T6247 defines a rock drill as a "machine with an impact and rotation mechanism for drilling and rock drilling", which is roughly correct, but the following three points are open to discussion:

(1) It should not be called a machine, but should be called an appliance or machine tool, because the rock drill is relatively simple in structure and has no power part, and needs to input hydraulic power or pneumatic power from the outside.

(2) It should be emphasized that the impact action is the main and the rotary cutting action is the supplement. Machines that are mainly rotary cutting and perforated by impact are generally called power heads, not rock drills.

(3) It is not pointed out that the rock drill can only be used for top hammer drilling. Although the DTH hammer is a percussion drilling, it cannot be called a rock drill.

4.3 Definition of power head

Machines that output torque and speed are called power heads. The volume, weight, output torque, and power of the power head are much larger than rock drills. The power head is generally used for drilling operations of rotary drilling rigs, pipe roof rigs, and bolting rigs.

5. Definition of drilling rig, drilling rig and trolley

5.1 Definition of drilling rig

The connotation of drilling rig is the most extensive, referring to all drilling equipment. Any equipment that can drill holes in soil or rock can be called a drilling rig, whether it is percussion, cutting, rolling, vibration or combined drilling, or mobile drilling equipment and fixed drilling equipment , Such as oil drilling rigs, geological core drilling rigs, etc., can all be called drilling rigs.

GB/T6247 defines a drilling rig as "a machine that mainly relies on a rotary mechanism to drill rock holes", which greatly reduces the connotation of the drilling rig, so that both DTH and top hammer percussion drilling equipment are excluded from the drilling rig . This is inconsistent with the actual situation in our country. Most manufacturers and users in my country refer to DTH percussion drilling equipment as DTH drilling rigs. The famous "Hometown of Drilling Rigs" in my country-Zhangjiakou Xuanhua mainly produces down-the-hole percussion drilling rigs. It is recommended to be revised when GB/T6247 is revised.

5.2 Definition of drill carriage

GB/T6247 defines a drill rig as a “car for drilling rock holes by a rock drill”. According to this definition, only the vehicle that uses the top hammer percussion rock drilling can be called a drill carriage, and the down-the-hole drilling equipment cannot be called a down-the-hole drill carriage. This is in contradiction with GB/T1590. In the category of drilling rigs, GB/T1590 includes multiple products such as open-air DTH drilling rigs, open-air medium-pressure DTH drilling rigs, open-air high-pressure DTH drilling rigs and open-air hydraulic DTH drilling rigs. name.

It may not be appropriate to define "drilling cart" as "car". In GB/T6104-2005, ISO 5053:1987, the classification of motor industrial vehicles includes trucks, tractors, pushers, stackers, forklifts, etc., but does not include drill trucks.

English words such as "drill rig" and "drill Jumbo" indicate drilling equipment, but do not have the meaning of "vehicle". The English words for vehicles include "vehicle", "car", "truck", etc. In the international arena, there are also very few reports on using "vehicle" to describe self-propelled drilling equipment.

"Rig" has the meaning of "drilling rig, drill stand, rig, platform", and refers to all drilling rigs in English.

"Jumbo" has the meaning of "behemoth". Compared with hand-held rock drills and outrigger rock drills, single-arm, double-arm and three-arm rock drilling rigs are of course giants, so "Jumbo" can be translated as rock drilling rigs.

"Wagon" originally means "four-wheeled carriage" and also refers to trains or train carriages. Later, wagon evolved into a name for a car model. In the current English materials of foreign drilling rig companies, it is almost impossible to use "wagon" to mean drilling rigs.

It is recommended to call self-propelled drilling equipment that travels faster as a drill rig. For example, a drilling rig that is turned by a car can be called a rig.

5.3 Definition of rock drilling rig

Underground top hammer percussive rock drilling equipment is called rock drilling rig. Underground construction equipment also includes bolting rigs, concrete spraying rigs and prying rigs, etc., referred to as rigs.

The connotation of the rock drilling rig is the narrowest, with only underground top hammer percussion drilling equipment. Underground top hammer percussive rock drilling equipment can be further subdivided into tunnel boring trolleys, roadway digging trolleys, mining trolleys, etc. Although "trolley" also contains the word "car", it emphasizes the word "tai". On this platform, one drill boom or two drill booms or three or more drill booms can be installed for drilling operations.

GB/T6247 does not include "rock drilling rig". In fact, the term "rock drilling rig" is widely used. It is especially common in railway tunnel excavation and underground mine excavation projects, and it has been established by convention. It is recommended that the rock drilling rig be defined when the standard is revised in the future.

Open-pit top hammer percussion drilling equipment is generally called a drilling rig, and should not be called a rock drilling rig. This is also a convention.

in conclusion

The names of commonly used drilling equipment are organized as follows:

(1) Fixed drilling equipment can only be called drilling rig;

(2) Drilling equipment using cone bits can only be called cone drills;

(3) Rotary cutting drilling equipment shall be called drilling rigs, such as cutting drilling rigs, rotary drilling rigs, etc.;

(4) The equipment that uses power heads for drilling should be called drilling rigs, such as pipe shed drilling rigs, top drive drilling rigs, etc.;

(5) DTH percussion drilling equipment should be called DTH drilling rig;

(6) The open-air top hammer percussion drilling equipment should be called the open-air top hammer drilling rig;

(7) Tunnel and underground top hammer percussion drilling equipment should be called rock drilling rigs;

(8) Drilling equipment for automobile modification should be called drill carriage;

(9) The driving speed is very slow, such as less than 10KM/h, it should be called a drilling rig.