What are the classifications and styles of shank adapter?

Related products Link:

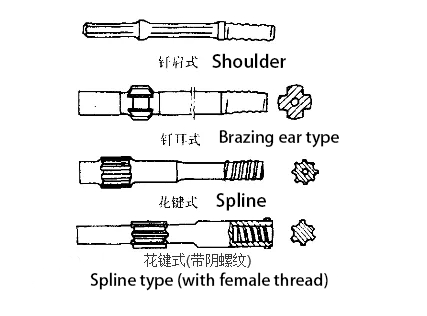

The cross section of the shank adapter is hexagonal, the diameter of the inscribed circle is 22mm and 25mm, and the length is 108mm and 159mm. It is manufactured by forging process and is used for light rock drills.

The lug type shank adapter is used for inner-rotating medium-sized guide-type rock drills, and the diameter of the drill rod is 25mm and 32mm.

The spline shank is often used for heavy-duty guide-type external rotary rock drills with large torque, and the diameter of the drill rod is more than 38mm. Manufactured by common machining methods.

The shank tails used in Chinese mines are mainly made of 35SiMnMoV or 24SiMnNi2CrMo steel, and the service life of the latter has been significantly improved.

The shank has a great influence on the rock drilling speed, the life of the rock drill and the drill bit. Therefore, the length of the shank should be appropriate, the end face should be flat and clean, the section should be perpendicular to the axis, and it should be in line with the drill socket of the rock drill (the gap should not be greater than 0.5mm). The hardness of the shank should be appropriate. If the shank adapter is too soft, the service life will be short. If it is too hard, the piston will be easily damaged. Generally, the hardness of the shank should be slightly lower than the hardness of the piston, and the quenching hardness HRC=38~45 is appropriate.

Special CNC machine tool processing equipment and processing technology should be used to ensure the processing quality of tail details, internal water holes and side water holes. The shank is uniformly heat treated, and scientifically straightened with precision instruments to ensure the straightness and resistance of the shank adapter.