Why does the drill bit of the rotary excavator get stuck during drilling?

Related products Link:

Rotary excavator is a comprehensive drilling rig, which can use a variety of bottom layers, has the characteristics of fast hole forming speed, less pollution, and strong maneuverability. The use of multi-layer telescopic drill pipes has less auxiliary time for drilling, low labor intensity, and does not require mud circulation to discharge slag, which saves costs. It is especially suitable for basic construction of urban construction.

1. In the process of drilling and lifting, the hole wall collapses in a large area, causing the drill to be buried and the drill bit is stuck;

2. Drilling too deep causes the hole wall to shrink, which causes the gap between the drill bit barrel wall and the hole wall to disappear and cause sticking;

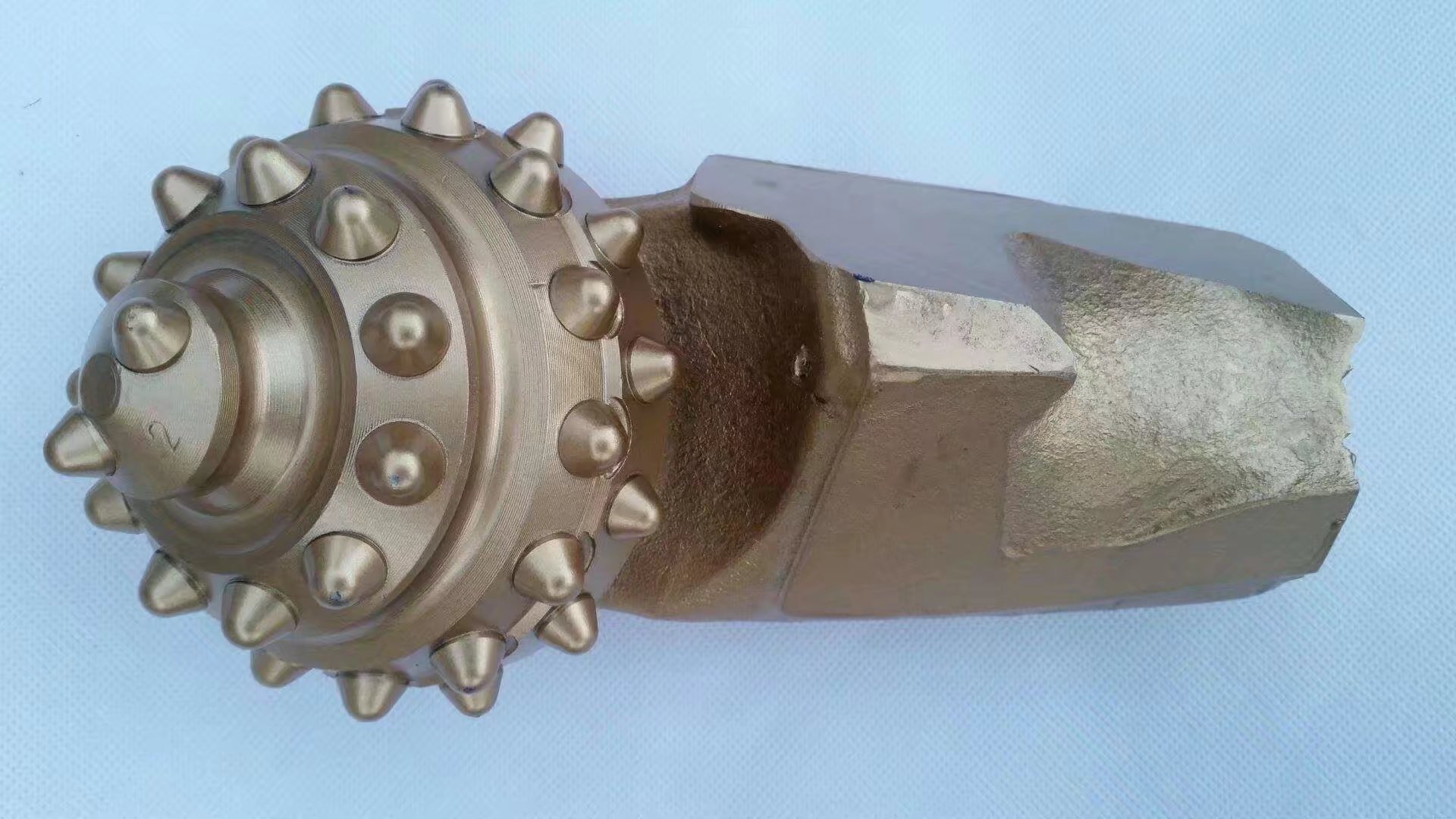

3. The side teeth and side teeth of the drill are severely worn, and the hole diameter cannot guarantee the size requirements, so that there is no gap between the outer wall of the drill barrel and the hole wall, and it is caused by drilling too deep.

4. The machine itself has some other failures (such as the engine can not work, the wire rope jumps out of the pulley groove, etc.) that suddenly stops the work, and the processing is not timely. The drill stays at the bottom of the hole for too long, resulting in too much or too much slag around the wall of the drill bit. The hole wall reduces in diameter.