- Gaea

- China

- 5-25天

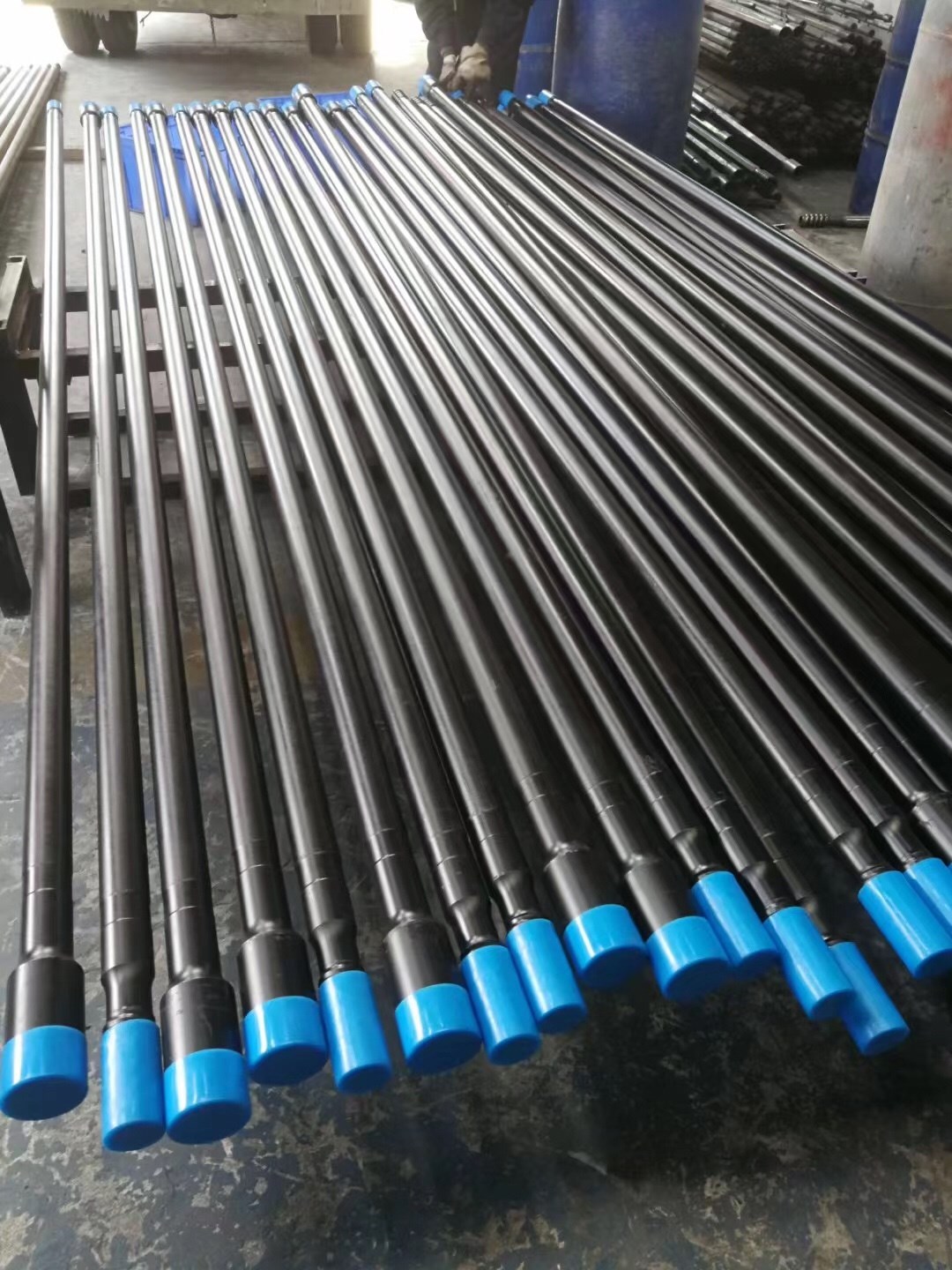

All our drifting and extension drill rods are heat-treated with carburization or high frequency, combinated with phosphorization.

Gaea Rock is drill rods manufacturers(drill pipe suppliers,drill pipe manufacturers).

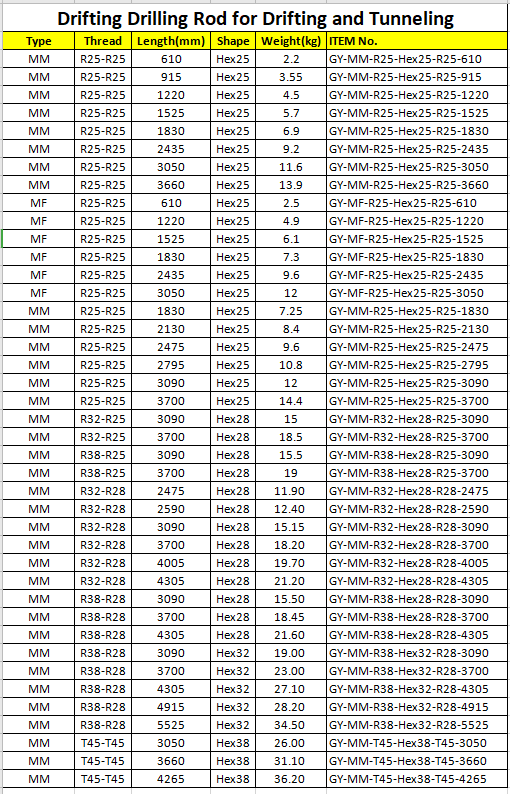

Extension Drill Rod Drilling Rod Rock Drilling tools MF MM

Related reports:

Share some tips for daily use of mining drill pipe;

Detailed analysis of round drill pipe, coal drill pipe, rock drill pipe;

After long-term use of blast furnace drill pipe, attention should be paid to maintenance;

Extension Rod introduction:

Extension Rod, also known as Drilling Rod, is a critical component used in various applications, primarily associated with hydraulic rock drilling and blasting operations. It is commonly utilized in conjunction with hydraulic rock drilling rigs, rock blasting holes, anchor bolt holes, and as a guiding rod. In some cases, it is also compatible with pneumatic rock drilling equipment such as the 90 drilling rig and vertical drilling machines.

During the operation of hydraulic rock drilling rigs and drilling machines, the drill string assembly, consisting of a drill bit, drilling rod, coupling sleeve, and tail rod, transmits the impact power of the hydraulic rock drilling machine. The drill bit directly engages in rock drilling operations, while the drilling rod experiences complex forces and demands stringent requirements due to its crucial role. As a result, the quality and performance standards for drilling rods are exceptionally high.

Extension rods can be categorized based on the equipment they are designed to be used with and the specific application fields. These categories include underground mining drilling rods for tunneling and rock excavation, underground medium-depth mining drilling rods, underground anchoring drilling rods, tunnel construction drilling and anchoring rods, as well as open-pit mining, quarrying, and surface engineering drilling rods.

In summary, extension rods, also referred to as drilling rods, are vital components used in hydraulic and pneumatic rock drilling applications. With their role in transmitting impact power and conducting rock drilling operations, the quality and performance requirements for these rods are rigorous. Their classification is based on the associated equipment and the application field, encompassing underground mining, tunneling, anchoring, tunnel construction, open-pit mining, quarrying, and surface engineering.

Our threaded drill pipes are not only widely used in the domestic market, but also sold overseas. They are widely used in mines, tunneling, surface mining, quarrying and other rock drilling operations. We are highly regarded by our customers for their excellent performance and reliability. We always put product quality first, and strictly follow international standards for production and inspection to ensure that products meet customer requirements.

As a customer of Liaoning Gaea, you will enjoy the following advantages:

High-quality products: We provide threaded drill pipes that meet international standards through strict quality control and testing processes to ensure their performance and reliability.

Diversified specifications and sizes: We provide threaded drill pipes of various specifications and lengths to meet the needs of different customers.

Customized solutions: We can provide customized threaded drill pipe solutions according to the specific requirements of customers.

Excellent after-sales service: We provide comprehensive after-sales support and technical guidance to ensure that customers receive timely help and support when using our products.

Extension Rod(drill extension rods)

Gaea is a professional manufacturer of rock drilling rod(water well drill rods), Rock drifting and extension drill rods(machining drill rod) are for in drifting, tunneling, long-hole drilling, bench and production drilling industries. These rods are produced with round or hexagonal sections in all common thread designs, and in Male/Male (M/M) or Male/Female (M/F) connections. All our drifting and extension drill rods are heat-treated with carburization or high frequency, combinated with phosphorization

Male/Female (M/F) rod, speed rod(tool steel drill rod)

It is common practice to bump up the drive end of drifting drill steel for added strength at the rock drill end to accommodate larger diameter and shank adapters. Drill steel of rock drilling tools is available in many standard lengths to match the drill feeds on a multitude of available drifting jumbos. A rock drill bit(thread button bits) diameter closer to the steel diameter can be used since the coupling does not enter the hole, this enhances flushing and hole accuracy.

Male/Female (M/F) Steel(mining drill rods)

Male/Female drill steel(mining drill rods) provides more rigid connections and is easier to uncouple and handle. The service life also tends to be better than with separate couplings. This is fortunate because the coupling end cannot be replaced.

M/F drill steel(mining drill rods) is an alternative to couplings sleeves to include the female part of the threaded connection as an integral part of the drill steel. M/F drill steel provides more rigid connections and is easier to uncouple and handle. The service life also tends to be better than with separate couplings. The advantages of drilling with M/F steel include: Easy handling, quicker uncoupling, tighter connections, the potential to drill straighter holes, and longer service life.

The round cross sections are more prevalent for extension drilling applications. A round rod has less material and thus is lighter to handle and less expensive than an equivalent size hexagonal rod. While hexagonal rod is particularly advantageous for drifting and tunneling drilling. The increased rigidity of hexagonal drill rods enables them to abating hole-deviation and enhances flushing for cleaning holes. Even with the larger cross section, hexagonal steel can still accommodate the same diameter bit as that of an equivalent round steel.

M/F rods provides tighter connections and is easier for handling and quicker for uncoupling than M/M rods, and are potential to drill straighter holes.

Carburization technique is mainly used in the production of big diameter rods to ensure excellent performance. Carburizing is for hardening entire rod to provide an external over entire rod surface area. Carburized steels are used primarily in underground applications and where water is used as a flushing medium. High Frequency technique is primarily used in the production of small diameter rods to reduce fragileness of drill steels. High Frequency is for hardening only the thread ends of the rod. This provides the longevity of the product as well as being more suitable for more drilling condition need. Steels produced with this technics primarily used in surface drilling applications where air is the primary flushing medium. Phosphorising is to improve anti-erosion capability of the entire external rod surface area.