- Gaea

- 中国

- 5-25天

Cemented carbide tapered button bits are made from high quality cemented carbide, produced with advanced technology and equipment, having different types bits, such as tapered chisel bit, tapered cross bit and tapered button bit which connected with tapered drill rod well for drilling hole, inserting depth is 25-30mm, obtaining maximum drilling speed, keeping stable and lowering rock drill working parameters so that prevent single button under overload then cause the button broken or lost

Q7 Tapered Button Bits Rock Drill Steel And Bits Dth Hammer Rock Drill Steel And Bits

Related reports:

What is the effect of choosing a reasonable drill bit and rod size

How to use button/column drill bit

According to the purpose of the drill bit

Introduction of the taper button bit:

Welcome to Liaoning Gaea, a trusted provider of high-quality drilling equipment and tools. We are committed to meeting the diverse needs of our valued customers worldwide. Today, we are excited to introduce our exceptional Q7 Tapered Button Bits, which have gained widespread recognition for their superior performance in a variety of applications.

Our Q7 Tapered Button Bits, also known as Q7 drill bits, are specifically designed and engineered to excel in open-pit mining, quarrying, hydropower projects, water well drilling, and excavation support tasks. These versatile tools showcase exceptional durability, reliability, and efficiency, making them the preferred choice for professionals in these industries.

The key feature of our Q7 Tapered Button Bits lies in the strategically placed buttons on their surface. These buttons, made from high-grade materials and manufactured using our advanced hot-insertion process, provide enhanced cutting and drilling capabilities. The Q7 drill bits offer exceptional wear resistance, ensuring extended service life and consistent performance even in the harshest operating conditions.

In open-pit mining operations, our Q7 Tapered Button Bits play a critical role in efficient ore extraction. Their superior drilling performance allows for increased productivity, reduced downtime, and cost-effective mining operations. These bits are designed to withstand the demanding conditions encountered in open-pit mining environments.

Quarrying operations also benefit from the exceptional performance of our Q7 Tapered Button Bits. Their precise drilling capabilities and extended service life make them ideal for rock excavation, stone cutting, and block extraction. The Q7 drill bits enable quarry operators to achieve efficient and high-quality stone production, contributing to increased productivity and profitability.

In hydropower projects, our Q7 Tapered Button Bits are relied upon for drilling tasks, including water well drilling. Their exceptional drilling efficiency and accuracy ensure the successful completion of drilling projects, providing access to vital water resources for various applications.

Furthermore, our Q7 Tapered Button Bits excel in excavation support tasks, such as the construction of retaining walls and excavation of foundation pits. Their reliable drilling performance enhances the safety and stability of excavation projects, facilitating smooth progress and minimizing the risk of structural instability.

Choose Liaoning Gaea for all your drilling equipment needs, and experience the unmatched performance and versatility of our Q7 Tapered Button Bits. Contact us today to learn more about how our tapered drill bits can revolutionize your operations and help you achieve unparalleled success in your industry. Trust in our expertise and commitment to excellence, and let us assist you in reaching new heights in your drilling endeavors.

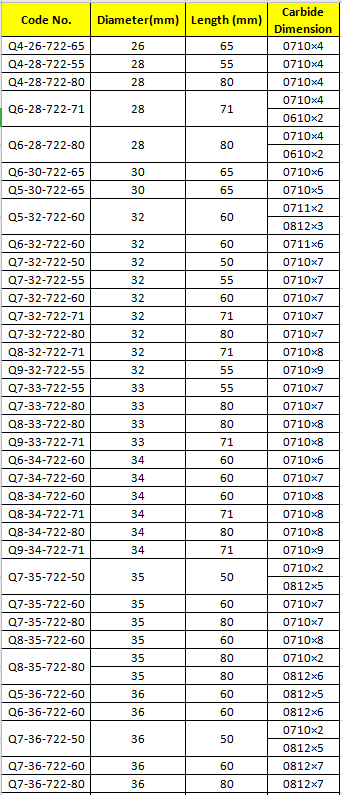

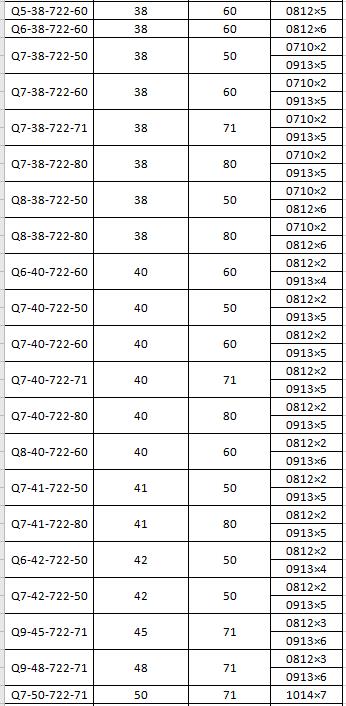

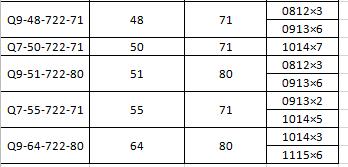

Parameter of the taper button bit:

Cemented carbide tapered button bits are made from high quality cemented carbide, produced with advanced technology and equipment, having different types bits, such as tapered chisel bit, tapered cross bit and tapered button bit which connected with tapered drill rod well for drilling hole, inserting depth is 25-30mm, obtaining maximum drilling speed, keeping stable and lowering rock drill working parameters so that prevent single button under overload then cause the button broken or lost.

Tapered Button Bits

Comparing with tapered chisel and cross bits, button bits has higher technology, much longer primary drilling time and higher drilling efficiency. According to the tungsten carbide insert, tapered button bits can be divided into the types of hemispherical, conical and parabolic button.

Cemented carbide tapered button bits widely used in gold mining, geological drilling, railway, highway, water conservancy and hydropower, tunnel working and granite and marble quarrying.

Advantages of Our Tapered Drill Bits:

1. Our products can match over 90% against the original products e.g Atlas Copco or Sandivik but being sold at much lower prices

2. Price are competitive against the famous brands and best quality against the small factory

3. Our factory has been specialized in manufacturing drilling tools and spare parts for over 10 years.

4. We have advanced technology and equipment.

5. Our technician has more than 20 year’s professional working experience.

6. Rock drilling tools are exported throughout the world. Main market: Saudi Arabia, India, Philippines, Norway, Sweden, China,South Africa

Packing details : Plastic packaging box and Wooden Case as required.

The service life of the button bit is determined by the internal quality of the product, scientific selection and correct use method. Drill bit products are inherently inferior in quality, no matter how they are selected and used carefully, the drilling footage (life) will not be high. On the contrary, no matter how good the quality of the product is, no matter how scientific the choice is, improper methods in the operation and use of the product will also cause the product to fail prematurely and fail to perform at its expected level. The main specifications of the button bit are: 28, 30, 32, 36, 38, 40, 42, etc., using passivation treatment, longer service life, and its non-grinding life is about 5 times the life of the same diameter blade bit. -6 times.

Specification: