Detailed analysis of round drill pipe, coal drill pipe, rock drill pipe

Related products Link:

The contradiction between strength and toughness is often encountered in the production and manufacture of drill pipe. In the current well drilling process, most of the wellbores are not vertical, and the application of inclined wells and horizontal wells is increasing. Drill pipe is a kind of product that requires relatively high precision. It is widely used in mining and coal mining industries. Its quality problem is everyone's attention. However, it will definitely be damaged during use.

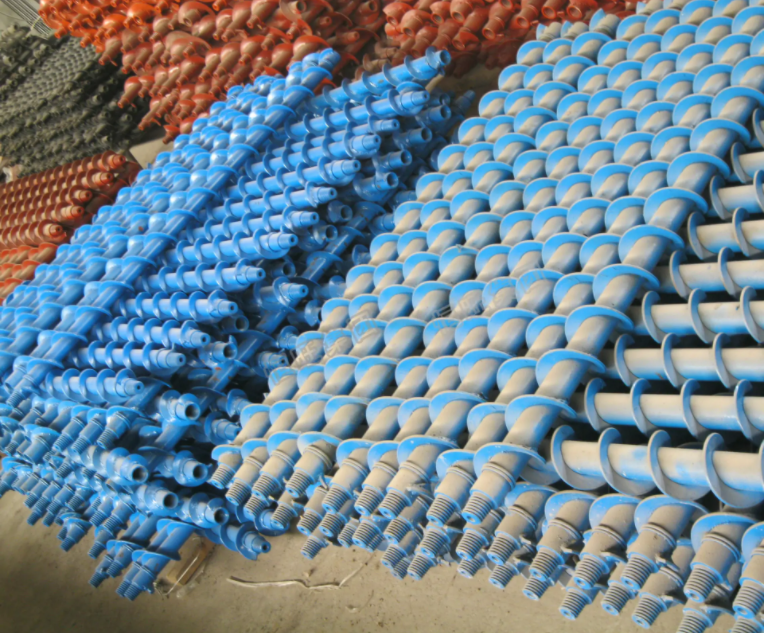

The auger rod is based on the high torque performance of the geological drill rod, using a single helical blade or a double helical blade, prestressed winding, and fully automatic welding. We are also called auger rods with diameters below 42mm. Geological auger pipes with a diameter of less than 73mm can be used directly with various mine tunnel drilling rigs, without changing the way of use, the drilling rig directly clamps the outer circle to drill and replace the drill pipe, which is convenient and quick, and greatly reduces the labor of workers. strength.

The geological auger pipe is mainly suitable for deep hole drilling construction in the geological conditions above medium hard and has the function of slag discharge; the auger pipe is suitable for the drilling construction of water exploration under the geological conditions of coal seam and near coal seam. The slag discharge speed is fast and so on. According to the principle of "select low-grade drill pipe as much as possible on the premise of meeting the strength requirements", the user selects the appropriate drilling tool for drilling operations according to the actual situation on site, which not only reduces the procurement cost, but also reduces the occurrence of accidents. probability.

Classification of drill pipe joints. There are four types of threaded drill pipe joints: inner flat (IF), through-hole (FH), regular (REG); digital (NC). Buckle connection conditions Three conditions must be met for buckle connection: ①Equal size; ②Same thread type; ③Matching male and female buckles. The basic working principle of auger pipe: the main power system of auger pipe is drilling fluid and motor. The drilling fluid pumped by the mud pump is drilled into the hydraulic motor of the auger pipe, and a certain pressure difference is formed at the inlet and outlet of the motor. This pressure difference drives the rotor of the motor to rotate, and transmits the torque and speed through the universal shaft and transmission. The shaft is passed to the drill.

Conducting non-destructive quality management inspections, Gaea Drilling Tools then performs steel pipe body joint welding. Welded joint residual stress is then eliminated by welding heat treatment and welding final treatment. Other tests such as hardness testing, pressure testing, non-destructive testing, etc. must be performed on the finished steel pipe before painting and packaging the finished drill pipe. Mine pipes and round steel pipes are made with drill pipe after several processing stages. First, through the processing of the steel pipe thickening process, the appearance of the light pipe is bent towards the inside, and the steel pipe wall is thickened. Next, threading is performed and copper is plated for strength.

The drill pipe body is made of special alloy steel pipe for geology, and the drill pipe joint is made of alloy structural steel, which has been treated with vacuum air conditioning, which greatly improves the fatigue strength and shear strength. Produced and processed by advanced friction welding process, Gaea drill pipe has the characteristics of high bending strength and firm welding. Drill pipe (twist drill pipe) usage: When the twist drill pipe is used to hit the anchor cable hole, the coal (rock) powder will be discharged out of the hole with the helix of the drill pipe, so there is no need for water supply and dust removal, and the roadway is excavated at a depression angle. It can reduce the water accumulation in the coal head. The use of drill pipe and pneumatic coal drill can greatly improve the construction speed and construction quality of roadway.

Be careful to avoid mixing drill pipes of different buckle types, even if they are not produced by the same manufacturer, do not mix them (because the technical parameters, processing methods, props, and mechanical equipment of drill pipes manufactured by various manufacturers are different, and the tolerances and tightness of the drill pipes processed are different. distance, etc. must be different); the difference between the old and the new is too large, and the drill pipes with too much wear and tear should not be mixed to avoid construction hazards. It is found that the drill pipe buckle type has local small-scale damage (about 1-2 buckles, the buckle length is 10mm), and it should be repaired in time before use.