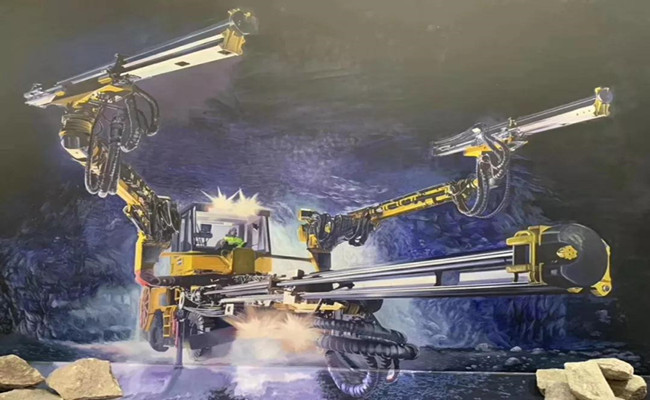

Three-arm trolley

Related products Link:

1. Problems in the management of fully computerized three-arm trolley

(1) The construction unit has insufficient understanding of the characteristics of the fully computerized three-arm trolley, and insufficient attention, which is equivalent to the management of conventional equipment.

(2) There is no professional organization for professional management, the sense of belonging of the personnel is not strong, the equipment efficiency is not fully utilized, the intact rate is low, and the downtime is long.

(3) The company has not cultivated its own trolley management, operation, and maintenance team, and blindly recruits people from the society with high salaries, low quality of personnel, short-term behavior, high consumption, high cost, and high equipment failure rate.

(4) Systematized and normalized management of all computer trolleys is not carried out from the perspective of the entire life cycle of the equipment, the idle rate is high, and the overall equipment efficiency is poor.

2. Specialization is the inevitable way to improve the management level of fully computerized three-arm trolley

2.1 Fully understand the characteristics of the fully computerized three-arm trolley, and have a targeted management

Compared with the hydraulic three-arm trolley, the fully computerized trolley has a higher degree of automation, the total station is positioned, and the pocket surface is positioned quickly and accurately; the computer can assist in the layout of the holes and generate the layout map, without the need to manually arrange points on the pocket surface. Improve work efficiency; with computer operation, drilling accuracy is less dependent on the operator, and it is easier for new students to get started; RCS computer automatic control, accurate positioning, fast drilling, and low drilling tool loss; fully computerized three-arm trolley per unit per shift Only 2 operators are required, which can reduce 1 operator compared to hydraulic three-arm trolleys, saving labor costs; the trolley is equipped with a tunnel profile scanner, which can export hole layout and drilling records, which is convenient for analysis and correction of drilling and blasting Design to control and improve over-under-excavation. With the improvement of the stability of the control system and the reliability of the sensors, the applicability of the all-computer trolley will increase, and the scope of application will become wider and wider. It should be the direction of future development. Compared with hydraulic trolleys, the disadvantages of fully-computerized trolleys are higher purchase costs, high requirements for the quality of management personnel, operation and maintenance personnel, and professional management agencies for professional management.

2.2 Establish a professional management organization and implement professional management

2.2.1 It is imperative to implement professional management

The computerized three-arm trolley is difficult to adapt to the large-scale, special-purpose, advanced, complex, and highly intelligent model of equipment management by the project's physical machinery department. It is necessary to establish a professional management organization, independent accounting, formulating rewards and punishments, and supporting corresponding Management systems and methods. The basic goals pursued by equipment management are intact rate, utilization rate and equipment profitability, and the management of three-arm rock drilling rigs must be accompanied by a professional goal, namely, over-under-excavation control. The professional management organization of the three-arm trolley shall incorporate the equipment for tunnel mechanized operation into unified management. There are fewer equipment or operating points in the early stage, which can be a team organization. If this number is exceeded, a tunnel mechanization branch company should be established, and a substantive and rigid management organization should be established, so that every piece of equipment is under the professional management of a professional organization, and the equipment's life cycle management is truly realized.

2.2.2 Advantages of establishing a tunnel mechanization branch

Implement professional management to ensure that the pipes, use, maintenance, and repair of large equipment (three-arm trolley, arch frame trolley, arch anchor trolley, wet spray manipulator, etc.) are managed by professional institutions to ensure the integrity rate. Implement professional management to ensure that professional equipment increases the utilization rate and realize equipment profitability. Ensure the construction of professional talents, personnel have a sense of belonging and sustainable development. It can improve the level of professional construction, such as rapid tunnel excavation, over-under excavation control, etc. Substantive actions, market-oriented operations, small accounting units, and effective implementation of incentive measures. It can effectively solve the problem of insufficient equipment management capabilities of the project department.

2.2.3 The staffing of mechanized branches should be lean and efficient

The tunnel mechanization branch has 1 manager, 1 deputy manager, chief mechanical engineer, full-time deputy secretary each, and 4 team members, who can work part-time for lower-level positions; set up the Material Machinery Department, with 2 staff, and the chief mechanical engineer can concurrently serve; Set up 1 finance or cashier. These 7 personnel are core administrators. Each work site has a work team, two work sites and above, need to set up a tunnel mechanized work team, the implementation of the management of fixed personnel and machine, the implementation of the captain responsibility system, random walk, long-term management.

3. How to effectively implement the professional management of computerized trolleys

On the basis of perfecting the professional management system and establishing the tunnel mechanization branch, various management systems will be completed.

3.1 Improving the management mechanism and supporting corresponding management methods

The institutional setting should be conducive to the development of specialized companies, and only good institutions can cultivate and retain talents. First, formulate the "Administrative Measures for Tunnel Mechanization Branches", clarify the organization and personnel and equipment configuration, and set the business section, development direction, talent training, reputation and efficiency of the tunnel mechanization branch, and specify the three levels The division of management functions and work interfaces of the company, tunnel mechanization branch, and project department, the assessment of the branch by the three-tier company, and the assessment mechanism within the branch. Second, formulate the "Measures for the Management of Tunnel Mechanized Equipment" and formulate targeted management methods, including the selection criteria for operation and maintenance personnel, the implementation of the system of personnel and equipment, maintenance and reconstruction and overhaul advancement, mandatory maintenance, economic management, etc. related information. To ensure that the equipment is in good condition and improve the utilization rate. Third, formulate the "Management Measures for the Procurement of Large Machine Materials and Accessories", try to adopt a three-tier company centralized procurement method, clarify the procurement and acceptance standards of accessories, avoid the use of counterfeit, inferior accessories and oil, and reduce procurement costs. Fourth, formulate the "Large Machine Operation and Maintenance Personnel Salary Management Measures". There is a gap between the income of large machine operators, especially the operation and maintenance personnel of all-computer trolleys, and the market. The existing salary management methods cannot adapt to talents.

Cultivation and introduction, specially formulated "Large Machine Operation and Maintenance Personnel Salary Management Measures" to promote the professional development of all-computer trolleys. Fifth, formulate the "Skill Level Classification and Promotion and Salary Standards for Rock Drilling Trolley Operators". In order to create better mechanical benefits, the operators of all computerized trolleys should be trained by their own units, and recruited in the market auxiliary. A clear career plan should be carried out for the rock drilling rig operators, hierarchical management should be carried out according to operating skills and business capabilities, and the conditions for promotion and matching salary standards should be formulated, so that highly skilled operators can see hope. Sixth, formulate the "Mechanized Tunnel Construction Reward and Punishment Measures", formulate a complete set of assessment methods, establish incentive and restraint machinery, and stimulate the vitality of the system. Rewards and punishments should be assessed from multiple dimensions such as cyclical footage and monthly progress, control of over-under-excavation, repair and maintenance, consumption of accessories and drilling tools, intact rate, and safety. The method should be simple, executable, and easy to calculate, so that every An operator and maintenance personnel can calculate the rewards and punishments themselves. Seventh, formulate the "Implementation Rules for the Management of Fully Computerized Rock Drilling Trolleys", highlight key points, and effectively manage and control the trolleys to keep the trolley in good condition.

3.2 Straighten out the relationship with the project department, achieve three major benefits through win-win cooperation

The tunnel mechanization branch company is positioned as a professional permanent organization for the management of fully computerized three-arm trolleys, which implements market-oriented operations and substantive actions; while the project department is a temporary organization established to complete a certain project. As the project is completed And disbanded. The working interface of the two should be clear, and the tunnel mechanization branch company should provide mechanized professional construction services for the project department in the mode of internal professional contracting. It should work closely with the project department to achieve a win-win cooperation in order to achieve economic, social, and talent benefits smoothly.

(1) The tunnel mechanization branch company can set up multiple tunnel mechanization operation teams (or teams) according to the construction tasks, and each operation team serves as an economic accounting unit.

(2) The tunnel mechanization branch has a contractual relationship with the project department. The tunnel mechanization construction can be undertaken in the form of process contracting or professional contracting. It is best to undertake the entire tunnel (or a tunnel with two tunnel faces). Mechanized construction is conducive to process connection and rapid excavation, the overall efficiency of supporting machinery is also beneficial to safety and quality control, and effectively reduces the cost of mechanization; the internal contract unit price is compared to the market price and is jointly determined by the third-level company, project department, and branch.

(3) Before the national quota for large-scale machinery is revised and increased, the cost of large-scale machinery is higher than the cost of manual excavation. Projects that adopt tunnel mechanized excavation should appropriately reduce the profit handed over to the company by the project department, which is conducive to the project department to give priority to tunnel mechanization The method of excavation is conducive to the improvement of the utilization rate of the fully computerized three-arm trolley.

(4) The project department is responsible for on-site supervision of the equipment and personnel assigned by the tunnel mechanization branch.

3.3 Equipped with strong operation and maintenance personnel, and implement professional management of personnel and machines

The operator of the fully computerized three-arm trolley should choose a naked eye vision of 1.0 or more, good physical coordination, understanding of machine, electricity, hydraulics, basic knowledge, love of the mechanical industry, and college-level or higher mechanical and related majors who can adapt to field work. It takes the form of factory training + on-site training, and it usually takes more than half a year to have the basic operation and maintenance capabilities of the hand-held face. As a large-scale professional equipment, a fully computerized trolley must implement a management system based on its advanced nature and complexity. Each vehicle must have a captain and a driver in charge, and clarify its management responsibilities and rewards and punishments.

3.4 Formulate broadband salary and assessment, unblock promotion channels, and retain professional talents

Although the operators and maintenance personnel of the full computer trolley can be recruited from manufacturers or service organizations with high salaries, it can alleviate the shortage of personnel in the short term, but it is not a long-term solution. The social mobility of external personnel, quick success and short-term behavior, etc. The core personnel for the operation and maintenance of the full-computer trolley should be cultivated by the company itself, and the third-tier companies should formulate broadband salary and assessment to smooth the talent promotion channel. The management staff of the full-computer trolley implements the form of basic salary plus performance, and the daily salary can refer to the same level standard of the project department; the cash is implemented in accordance with the contract evaluation method. Operators and maintenance personnel who have reached a certain working life and have reached the corresponding work ability after assessment should be given corresponding rank promotions and corresponding remuneration packages; remuneration packages should be basically equal to market prices to prevent brain drain.

3.5 Fully computerized trolley for rapid excavation, control over excavation and under excavation and use management

3.5.1 Rapid excavation of fully computerized trolley

One hour before the completion of the concrete spraying operation in the previous process, the operator of the full-computer trolley should be notified to rush to the scene, check and start the trolley, and travel outside the mobile trestle to wait. After the wet spray manipulator exits the trestle (excavation on the face The machine has cleaned up the section), the trolley is opened on the trestle until the palm is in place (two trolleys generally take 10-20 minutes), the trolley is positioned with a total station for about 5 minutes, and the water and electricity are connected. The hole layout has been input into CRRC's operating system, and the trolley will start drilling.

3.5.2 Measures to control over excavation and under excavation by trolley excavation

Summary of each shift, timely adjustment of drilling and blasting parameters. Trolley rock drills are large in size, and the external insertion angle is not easy to control, which can easily cause large over and under excavation. After each shift is completed, the squad leader must lead the operators, artillery, and technicians to the face to check the blasting effect in time. Summarize experience and deficiencies, and adjust or modify drilling and blasting parameters in time. Form an effective reward and punishment system. According to the overdigging situation of each class, rewards and punishments are given to individuals in time after the class, and cashed in time. Timely summarize the over-under-excavation situation of the month, commend the advanced, penalize the backward, and encourage the operators to learn from the advanced. Strengthen the education and training of operators, so that every operator deeply realizes the importance of drilling accuracy, and completes every drilling operation accurately and efficiently.

3.5.3 The use and management of the full computer trolley

(1) The tunnel mechanized operation team shall carry out the use and maintenance of the trolley, train the operators, and formulate relevant management systems in accordance with the operating instructions, safety technical operating procedures, maintenance procedures and other technical documents of the fully computerized rock drilling rig. Establish and complete the responsibilities of each position with the rock drilling rig, and implement the maintenance responsibility system.

(2) Professional operation of rock drilling rigs. The operator of the rock drilling rig must be professional and sophisticated, and under the premise of ensuring the quality of the hole, standardize the operation, strive to study the drilling technology, improve the drilling skills, and improve the overall efficiency of the use of the rock drilling rig.

(3) Strive to achieve "two targets". That is, the integrity rate of the rock drilling rig operating cycle and the cyclic utilization rate of the rig operating cycle. Pursue 100% of the rock drilling rig operating cycle integrity rate and 100% of the rock drilling rig operating cycle utilization rate.

3.6 Strengthen maintenance to ensure equipment integrity rate

(1) The fully computerized rock drilling rig must implement the "1+1" mandatory maintenance mode, that is, one shift must be used, and one shift must be maintained, pursuing a 100% integrity rate of the face drilling cycle. At the same time, parts management should be strengthened, and core parts such as rock drills, hydraulics, and electric controls should be 100% original parts to increase service life and ensure maintenance quality.

(2) Maintenance work must be enforced in accordance with regulations, and maintenance work must not be stopped or postponed under any excuse or reason.

(3) The maintenance work must be done by a dedicated person, the maintenance procedure is reasonable, the maintenance method is correct, and the maintenance process is supervised. It is strictly forbidden to replace the maintenance work with repair.

(4) The maintenance work is guided by professional and technical personnel, and the failure is handled in a timely manner, and detailed maintenance process records are made to ensure that the equipment is in good condition.

(5) It is strictly forbidden to substitute parts for different purposes at will, and important accessories should meet the requirements of the original machine; it is strictly forbidden to disassemble safety and indicative sensors, safety valves, instruments, overflow valves, etc., if damaged or inaccurate, promptly replace.

(6) The maintenance of rock drilling rigs implements the principle of "equal attention to maintenance and precautions", attaches importance to maintenance, and performs "class inspections", "weekly inspections" and "monthly inspections" in a planned way. A combination of maintenance, regular maintenance and mandatory maintenance.

3.7 Professional construction, open more working faces, and give full play to the efficiency of the full computer trolley

Project departments that use fully computerized trolleys for face excavation should change the subcontracting mode to create conditions for the full-process construction for large machines. At least the excavation, support, concrete spraying, slagging, and roofing processes should be performed The implementation of the tunnel mechanization branch is more conducive to the performance of the full computer trolley. The whole process of the tunnel is completed by a professional team, which is more conducive to the close connection of the processes, reducing internal friction, and giving play to the advantages of large machines.

4. Conclusion

The third-level integrated engineering company should strengthen the professional management of the full-computer three-arm trolley, set up an organization, support corresponding management methods, formulate incentive and restraint mechanisms, clarify responsibilities and rights, divide economic accounting units, timely rewards and punishments, and increase staff motivation ; Establish a long-term talent training and growth mechanism, let talents have a sense of belonging, and truly realize the life cycle management of the entire computer trolley.