- Gaea

- 中国

- 5-25天

- 30sets/month

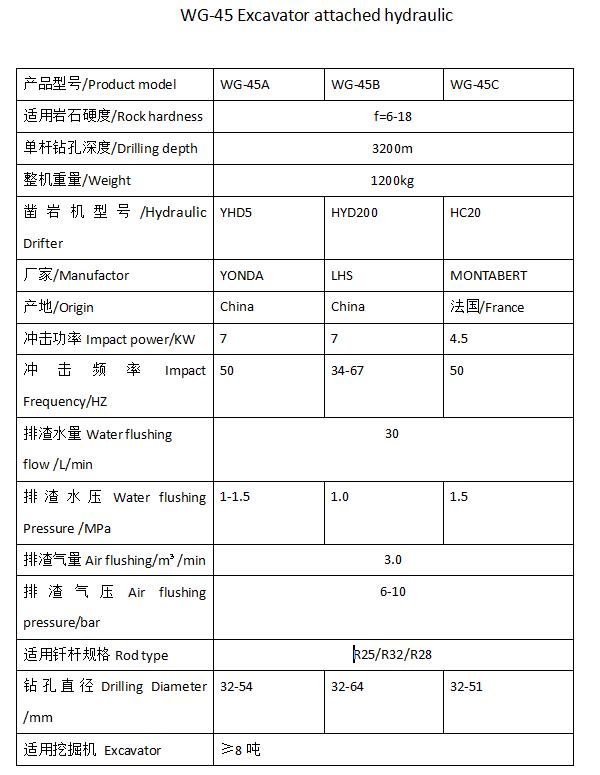

The WG-45 excavator drill rig combines a rock drill and excavator for powerful rock drilling, versatile excavation and precise control. This excavator drill rig uses high-frequency piston impact crushing for efficient penetration; durable components, an ergonomic cab and safety features cut downtime and fatigue. Yantai Gaea’s WG-45 excavator drill rig suits mining, tunneling and construction.

Excavator Drill Rigs

Related reports:

Application and analysis of rock drilling rig in mountain tunnel construction;

The composition and working principle of drilling rig equipment;

The WG-45 Rock excavator drill rig and Excavator, which combines the functionalities of a rock drilling rig and an excavator to deliver exceptional performance and versatility in various applications.

The WG-45 is a state-of-the-art machine designed to meet the demanding requirements of rock drilling and excavation projects. This robust equipment incorporates advanced technologies and features, making it a reliable and efficient solution for your drilling and excavation needs.

Key Features of WG-45 Rock excavator drill rig and Excavator:

Powerful Rock Drilling Capability: The WG-45 excavator drill rig is equipped with a high-performance rock drilling system, enabling it to penetrate even the toughest rock formations with precision and speed. Its exceptional drilling power ensures efficient and reliable operation in challenging geological conditions.

Versatile Excavation Functionality: As an excavator, the WG-45 excavator drill rig offers exceptional versatility in handling various materials, including rocks, soil, and debris. With its advanced hydraulic system and robust bucket capacity, it efficiently excavates, loads, and transports materials, enhancing productivity on your job site.

Precision and Control: The WG-45 excavator drill rig is engineered to provide precise control over drilling and excavation operations. Its user-friendly interface and ergonomic controls allow operators to adjust parameters and settings easily, ensuring accurate and efficient performance.

Durability and Reliability: Built with high-quality materials and components, the WG-45 excavator drill rig exhibits excellent durability and reliability, even in demanding working conditions. It is designed to withstand rugged environments and prolonged operation, minimizing downtime and maximizing productivity.

Safety and Operator Comfort: Yantai Gaea prioritizes safety and operator comfort in the design of the WG-45 excavator drill rig. The machine is equipped with safety features, such as emergency stop buttons, protective guards, and advanced monitoring systems. Additionally, the operator's cabin offers a comfortable and ergonomic workspace, reducing operator fatigue and enhancing overall efficiency.

With the WG-45 excavator drill rig and Excavator, you can streamline your drilling and excavation operations while enjoying the benefits of a versatile and high-performance machine. Whether you are working on mining projects, construction sites, or infrastructure development, the WG-45 excavator drill rig is an ideal choice to enhance your productivity and achieve exceptional results.

We at Yantai Gaea pride ourselves on delivering reliable and innovative machinery to our valued clients worldwide. Our team of experienced professionals is committed to providing exceptional customer service, technical support, and after-sales assistance to ensure your satisfaction.

To learn more about the WG-45 excavator drill rig and Excavator or to request a quotation, please feel free to contact us. We are available to answer any questions you may have and provide further information on the product specifications, pricing, and delivery options.

Thank you for considering Yantai Gaea as your trusted partner for your rock drilling and excavation needs. We look forward to the opportunity to serve you and contribute to the success of your projects.

The excavation and modification of rock drilling machine works according to the principle of impact crushing. During working, the piston makes high-frequency reciprocating motion, which constantly impacts the shank adapter. Under the impact of the impact force, a sharp wedge-shaped drill bit crushed the rock and chiseled to a certain depth, forming a dent.

Drilling land rigs,After the piston retracts, the drill rotates at a certain angle, the piston moves forward, and when it hits the shank adapter again, a new dent is formed. The fan-shaped rock block between the two dents is shredded by the horizontal force generated by the drill bit. The piston continuously impacts the shank adapter and continuously feeds compressed air or pressurized water from the center hole of the drill to expel the rock slag out of the hole to form a circular hole with a certain depth.

Gaea specialize in supplying powerful limited access drilling rigs and hard rock drilling attachments for skid steers and excavators. Our rigs and excavator rock drills are built for pre-drilling hard rock, micro piling, geothermal, solar, foundation, dewatering, water well and geotechnical applications. We offer complete drill tooling packages and customized equipment options to suit your application and ground conditions, helping to maximize your drill speeds and project efficiency.

With over 40 years experience in the industry we offer some of the most powerful compact equipment and excavator rock drilling attachments available.

FAQ:

1.Can a rock drilling rig handle different types of rock formations?

Yes, rock drilling rigs are designed to handle various rock formations, including hard rocks, sedimentary rocks, and fractured rocks, with different drilling techniques and tooling options.

2.How can I ensure the safety of using a rock drilling rig?

Safety measures such as proper training, wearing personal protective equipment (PPE), regular maintenance, and following manufacturer guidelines are essential for safe operation of rock drilling rigs.

3.What maintenance is required for a rock drilling rig?

Routine maintenance tasks include checking and replacing worn-out parts, lubricating components, inspecting hydraulic systems, and monitoring overall rig performance to ensure optimal functionality.