- Gaea

- China

- 15 days

The hydraulic splitter is a machine that uses the wedge principle (which can release a great splitting force outward in the narrowest hole) for the mining of quarry blocks.

The hydraulic splitting machine grasps the brittleness of rock and concrete, and is designed using the principle of wedge-it can release a great splitting force outward in the narrowest hole.

hydraulic rock splitter manufacturers Diesel power rock splitter machine

Related reports:

The working principle and operation method of piston splitting rod;

Introduction to Piston Split Rod;

A brief introduction to the hydraulic rock splitter manufacturers;

Diesel-powered hydraulic rock splitter introduction:

The diesel-powered hydraulic rock splitter, proudly manufactured and distributed by Liaoning Gaea. As a trusted player in the industry, we are committed to delivering innovative solutions that redefine rock breaking in various applications.

The diesel-powered hydraulic rock splitter, also known as a diesel hydraulic stone splitter, represents a groundbreaking advancement in the field of rock breaking technology. Combining the power of a diesel engine with the precision of hydraulic force, our rock splitter offers unparalleled performance and efficiency, making it the preferred choice for demanding applications in mining, construction, and civil engineering.

At Liaoning Gaea, we understand the unique challenges faced by our customers in the field. That's why we have engineered our diesel-powered hydraulic rock splitter to deliver exceptional power and reliability, enabling efficient rock fragmentation even in the most demanding conditions. With its robust diesel engine, our rock splitter ensures consistent splitting force, allowing for rapid and effective breaking of rocks, boulders, and concrete structures.

The integration of diesel power provides several key advantages for our hydraulic rock splitter. The diesel engine offers exceptional torque and fuel efficiency, ensuring prolonged operation without compromising performance. This makes our rock splitter an ideal choice for remote locations or areas without access to electric power sources. Moreover, the diesel-powered hydraulic system delivers high-pressure force, enabling precise control and optimized fragmentation, thereby minimizing energy waste and maximizing productivity.

Safety is a top priority in our design philosophy. The diesel-powered hydraulic rock splitter incorporates advanced safety features to protect both operators and the surrounding environment. Our rock splitter is equipped with safety interlocks, emergency stop functions, and protective guards, ensuring safe and reliable operation. Additionally, the reduced noise emissions of the diesel engine contribute to a quieter and more comfortable working environment.

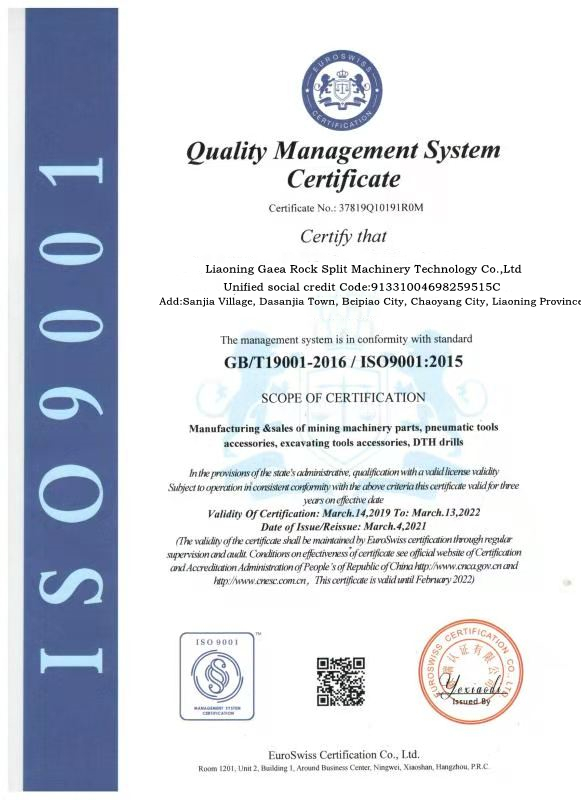

Liaoning Gaea takes pride in our manufacturing expertise and commitment to quality. We employ stringent quality control measures throughout the production process to ensure that every diesel-powered hydraulic rock splitter leaving our facility meets the highest industry standards. Our skilled technicians meticulously assemble and test each unit, guaranteeing durability, performance, and customer satisfaction.

We understand that customer support is paramount. Therefore, we provide comprehensive after-sales services to our esteemed clientele. Our experienced technical team is available to assist with installation, troubleshooting, and maintenance, ensuring that your diesel-powered hydraulic rock splitter operates at its peak performance throughout its lifespan. Furthermore, we maintain a readily available inventory of spare parts, ensuring minimal downtime in the event of component replacement.

In conclusion, the diesel-powered hydraulic rock splitter by Liaoning Gaea represents a breakthrough solution for efficient rock breaking. With its diesel power source, superior performance, and robust construction, our rock splitter delivers exceptional reliability and productivity in mining, construction, and civil engineering applications. Trust in our expertise, and experience the power and versatility of our diesel-powered hydraulic rock splitter.

For detailed information, technical specifications, and personalized assistance, please do not hesitate to contact us. We are committed to meeting your specific requirements and exceeding your expectations.

Hydraulic splitting machine product introduction:

Hydraulic splitting machine, also known as hydraulic splitting machine, is a machine used for splitting materials. It is mostly used in construction, decoration, engineering construction, and ore mining. The splitting machine is composed of two parts: a hydraulic power station and a splitting gun. The splitting machine is driven by the ultra-high pressure oil output from the pumping station to generate a huge driving force, and after mechanical amplification, the split object can be split in a predetermined direction . The hydraulic station supplies 60Mpa hydraulic oil to the splitting gun. The splitting gun can generate tens of tons of thrust. The splitting machine pushes the chip to expand on both sides, and the expansion force can reach several hundred tons, so that the object is split and separated from the inside. . The splitting machine is mainly used for construction stone mining operations: the secondary disintegration of large ore (metallic ores, non-metallic minerals); the partial and complete demolition of concrete components (cement pavement, machine tool foundation, bridge and building components), and the traditional Compared with the operation mode, the splitting machine has a series of advantages such as simple structure, convenient operation, high operation efficiency, low cost, safety, energy saving, and energy saving management.

The structure of the splitting machine: It is mainly composed of hydraulic station, oil pipeline, splitting gun, chip and so on. According to the type of power station, it can be divided into two types: electric type and diesel type. According to the material of the split gun, it can be divided into two types: steel split gun and aluminum alloy split gun. It can also be classified according to the power of the split gun.

The working principle of the splitting machine: 60Mpa pressure oil is supplied to the splitting gun from the hydraulic station. The splitting gun can generate dozens of tons of thrust and push the chip to expand on both sides. The expansion force can reach several hundred tons, so that the object can be moved from Split inside and separate.

Packaging:

FAQ:

1.Can a Hydraulic Rock Splitter be used in confined spaces?

Yes, Hydraulic Rock Splitters can be used in confined spaces. They are designed to be compact and versatile, allowing for effective splitting even in tight or restricted areas.

2.Is there a specific size range that a Hydraulic Rock Splitter can handle?

Hydraulic Rock Splitters are available in various sizes to accommodate different rock dimensions. The splitting force and wedge size can be selected based on the specific application requirements.

3.What is the maintenance requirement for a Hydraulic Rock Splitter?

Regular maintenance includes checking hydraulic hoses and connections, lubricating moving parts, inspecting and replacing worn-out wedges, and ensuring proper functioning of the hydraulic power unit.

4.Can a Hydraulic Rock Splitter be used underwater?

Yes, some Hydraulic Rock Splitters are designed for underwater use. They are equipped with waterproof seals and can operate effectively in submerged conditions.

5.How does a Hydraulic Rock Splitter compare to other rock splitting methods?

Hydraulic Rock Splitters offer advantages over traditional rock splitting methods such as blasting or manual techniques, including increased safety, reduced environmental impact, and precise control over the splitting process.