- Gaea

- 中国

- 5-25天

The part of the rock drill that bears the impact and torque of the rock drill. It should have the characteristics of high toughness and no plastic deformation. The brazing tail can be part of the brazing rod or can be made as an independent tail rod.

T38 Shank Adapter Drilling Shank Adapter

Related reports:

Factors affecting the efficiency of rock drilling tools;

Introduction to the heat treatment process of heavy drilling tools;

Introducing T38 Shank Adapter for Rock Drilling Operations:

The T38 shank adapter. Designed to meet the rigorous demands of rock drilling operations, this shank adapter is an essential component of rock drilling machines and drill string assemblies.

The T38 shank adapter features a T38 thread, which is a widely recognized thread type in the industry. This thread design ensures a secure and reliable connection between the shank adapter and the rock drilling machine, facilitating the efficient transfer of impact energy and rotational torque from the machine to the drill string assembly. With our shank adapter, the drill bit attached to the drill string effectively breaks down rocks, enabling successful rock drilling operations.

The shank adapter plays a critical role in rock drilling operations, as it not only withstands the high-frequency impacts and powerful torsion from the drilling machine but also endures the corrosive and abrasive effects of mining water and debris in the environment. Operating in such harsh conditions, the quality and performance requirements for the shank adapter are exceptionally strict.

To meet these demands, our T38 shank adapter undergoes advanced heat treatment during the manufacturing process. This heat treatment enhances the overall quality of the product, resulting in improved hardness, strength, and wear resistance. The use of heat treatment ensures that the shank adapter can withstand the extreme conditions encountered during rock drilling operations, reducing the need for frequent replacements and minimizing downtime.

The T38 shank adapter, also known as a shank adaptor, is a vital component that directly impacts the performance and efficiency of rock drilling operations. Its robust construction and high-quality materials enable it to withstand the demanding forces and harsh environments encountered during drilling. The reliability and durability of our T38 shank adapter ensure optimal performance, increased productivity, and cost-effective drilling operations.

In summary, the T38 shank adapter offered by Liaoning Gaea is a premium product designed for rock drilling operations. Its T38 thread, precise manufacturing, and advanced heat treatment process result in a shank adapter that delivers exceptional quality, durability, and performance. Whether it's high-frequency impacts, powerful torsion, or corrosive and abrasive conditions, our shank adapter excels, ensuring efficient power transmission and extended service life. Choose the T38 shank adapter from Liaoning Gaea for superior quality and reliable performance in your rock drilling applications.

Shank adapter(hammer drill adapter):

The part of the rock drill that bears the impact and torque of the rock drill. It should have the characteristics of high toughness and no plastic deformation. The brazing tail can be part of the brazing rod or can be made as an independent tail rod.

The brazing tail is mainly used in mining operations, using high-quality alloy steel as the raw material, after the overall carburizing treatment.

Gaea manufacture premium quality shank adapters(hammer drill adapter) for most brands of rock drills. While every component in the drill string is crucial, the shank adapter(hammer drill bit adapter) must be engineered to withstand the most extreme stress. Its function is to transmit impact energy from the rock-drill piston, as well as rotation torque, into the drill string withouth energy losses.

Application requirements:

The drill tail has a great influence on the rock drilling speed, the life of the rock drill and the drill. Therefore, the length of the drill tail should be appropriate, the end face should be flat and smooth, the cross section should be perpendicular to the axis, and it should coincide with the drill sleeve of the rock drill (the gap should not be greater than 0.5mm). The hardness of the solder tail should be appropriate. The life of the soft solder tail is short, and the piston is easy to be injured if it is too hard. Generally, the hardness of the solder tail should be slightly lower than the hardness of the piston. The quenching hardness HRC=38~45 is appropriate.

Special CNC machine tool processing equipment(high shank adapter) and process flow should be used to ensure the details of the tail, internal water hole and side water hole processing quality. The brazing tail is evenly heat-treated, and it is scientifically straightened using precision instruments to ensure the straightness and anti-irritability of the brazing tail.

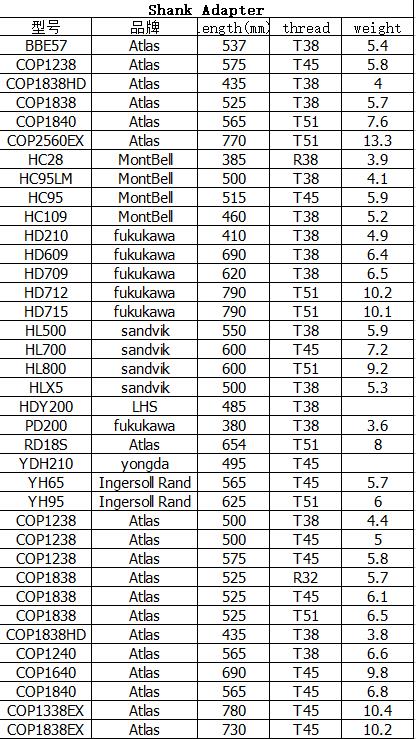

Code No.:BBE57-T38-460

Thread Type: T38

Length: 460mm

Rock Drill Type:BBE

Rock Drill Manufacturer: Atlas Copco

Code No.: COP1838HD-T38-435

Thread Type: T38

Length: 435mm

Rock Drill Type: Cop1838HD

Rock Drill Manufacturer: Atlas Copco

Code No.: COP1838-T38-525

Thread Type: T38

Length: 525mm

Rock Drill Type: Cop1838

Rock Drill Manufacturer: Atlas Copco

Shank Adapter Packaging:

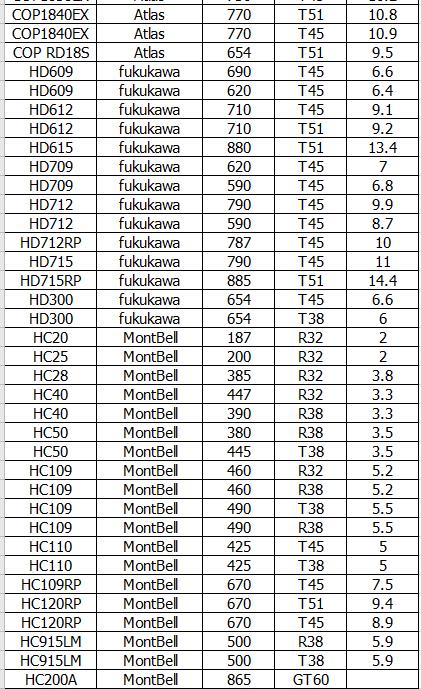

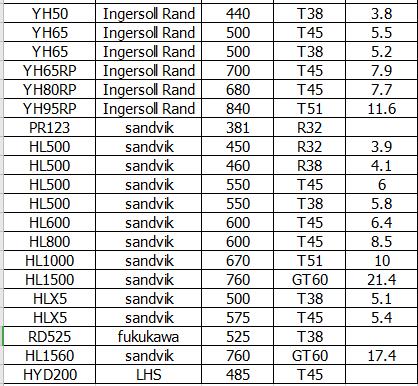

Specification: