- Gaea

- 中国

- 5-25天

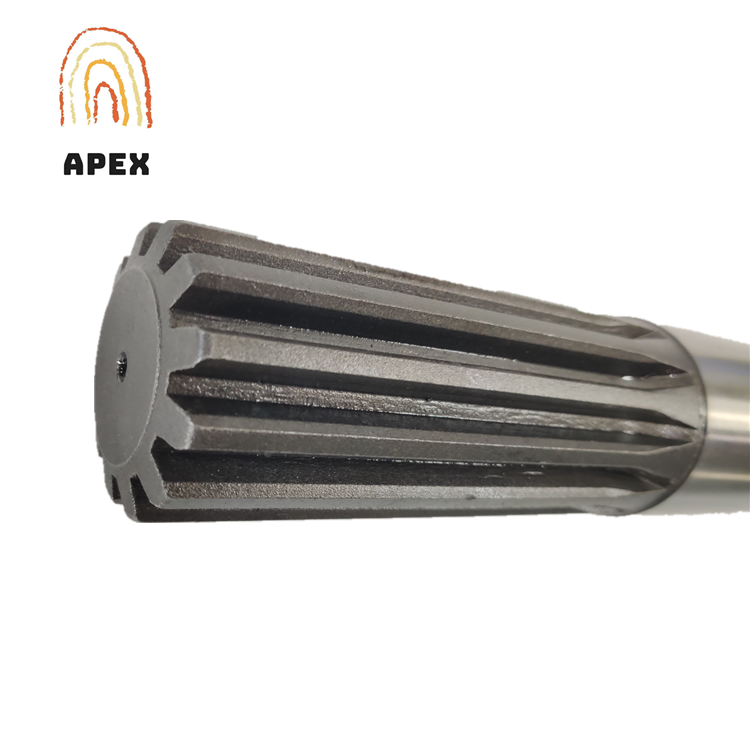

All of our tails are made of high-quality steel and then processed by cnc and carburized to ensure that they have excellent toughness and sufficient strength to meet the stringent requirements. Operating environment. In addition, according to the requirements, all the solder tails can be processed into male or female threads.

T51 Shank Adapter drilling Shank Adaptor

Related reports:

What are the classifications and styles of shank adapter;

The purpose and scope of application of shank adapter;

Introducing T51 Shank Adapter for Mining and Tunneling Operations:

The T51 shank adapter. Designed to meet the rigorous demands of mining and tunneling operations, this high-quality product is known for its exceptional performance, durability, and reliability.

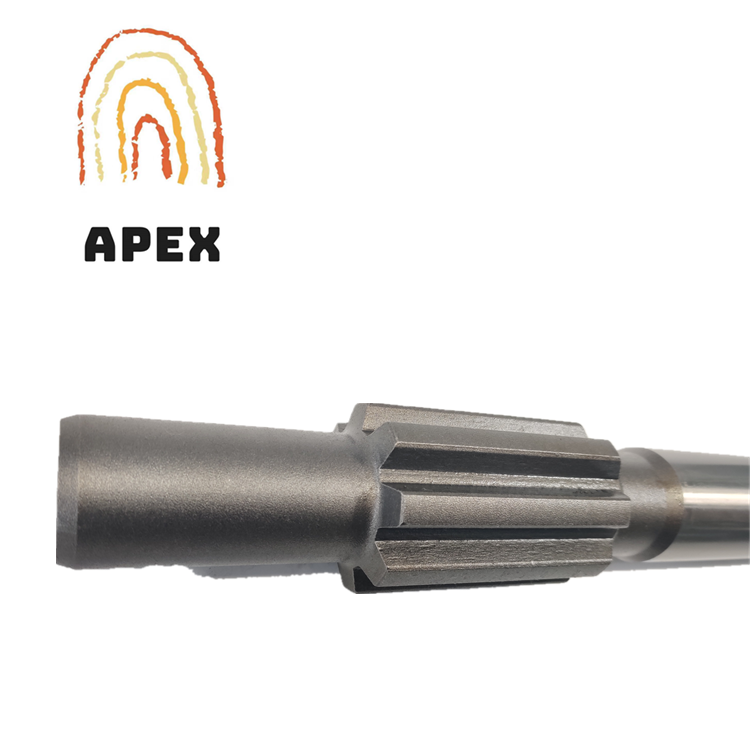

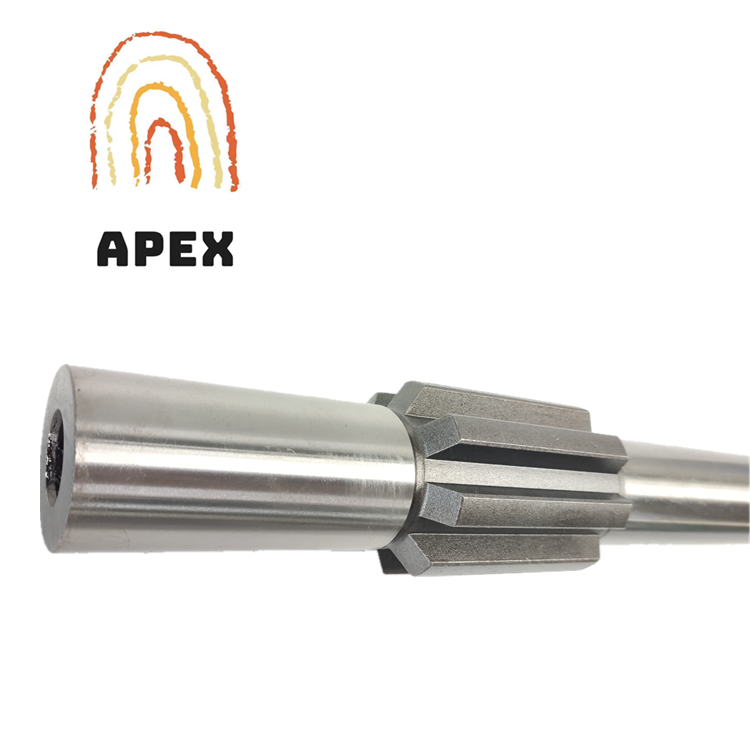

The T51 shank adapter features a T51 thread, which is widely recognized as a standard thread type in the industry. This thread design ensures a secure and reliable connection between the shank adapter and the drilling equipment, enabling efficient power transmission during rock drilling operations. Our shank adapter is meticulously manufactured using top-quality alloy steel and high-precision CNC machining equipment, ensuring outstanding durability and longevity.

One of the key features that sets our shank adapter apart is the implementation of advanced heat treatment during the manufacturing process. This thermal treatment enhances the overall quality of the product, resulting in improved hardness, strength, and wear resistance. By employing this state-of-the-art technique, we ensure that the T51 shank adapter can withstand the demanding conditions often encountered in mining and tunneling applications, reducing the need for frequent replacements and minimizing downtime.

In the shank adapter category, T51 is available in both male and female threads. The male-threaded shank adapter is more commonly used and suitable for applications such as mining, tunneling, and extension projects. On the other hand, the female-threaded shank adapter is used in areas with limited drilling space. Both variants are meticulously manufactured to meet the highest industry standards, ensuring optimal performance and compatibility with a wide range of drilling equipment.

Our T51 shank adapter is renowned for its exceptional durability and low energy loss. With its high-quality alloy steel construction, precise machining, and advanced heat treatment process, it boasts an extended service life, reducing the need for frequent replacements and enhancing overall drilling efficiency. This not only saves time and resources but also contributes to a more sustainable and cost-effective operation.

In summary, the T51 shank adapter offered by Liaoning Gaea is a premium product designed for mining and tunneling operations. Its T51 thread, precise manufacturing, and advanced heat treatment result in a shank adapter that delivers outstanding performance, durability, and reliability. Whether it's in the mining industry or tunnel excavation projects, our shank adapter ensures efficient power transmission, reduced downtime, and cost-effective drilling operations. Choose the T51 shank adapter from Liaoning Gaea for superior quality and reliable performance in your drilling applications.

Gaea produce supporting tails for most rock drills currently on the market. All of our tails are made of high-quality steel and then processed by cnc and carburized to ensure that they have excellent toughness and sufficient strength to meet the stringent requirements. Operating environment. In addition, according to the requirements, all the solder tails can be processed into male or female threads.

Male threads are generally suitable for sedimentary rock, tunneling and other extended applications. When drilling space and total feed length are limited and important, female threaded shanks are used, such as underground ceiling anchoring.

Our brazing tails are designed to withstand the high impact of modern rock drills. They are made of special steel materials and have undergone carburization to increase the surface hardness. Now we can provide about 300 different specifications of brazing tails to match Tras, Tom Rock, Sandvik, Furukawa, Montebello, Denver and other series of rock drills. We produce supporting tails for most rock drills currently on the market. All of our tails are made of high-quality steel and then processed by cnc and carburized to ensure that they have excellent toughness and sufficient strength to meet the stringent requirements. Operating environment. In addition, according to the requirements, all the solder tails can be processed into male or female threads. Male threads are generally suitable for sedimentary rock, tunneling and other extended applications. When drilling space and total feed length are limited and important, female threaded shanks are used, such as underground ceiling anchoring. The main role of the bit is to transfer torque, propulsion, impact and flushing medium to the drill pipe and bit. Our brazing tails are designed to withstand the high impact of modern rock drills. They are made of special steel materials and have undergone carburization to increase the surface hardness. Now we can provide about 300 different specifications of brazing tails to match Tras, Tom Rock, Sandvik, Furukawa, Montebello, Denver and other series of rock drills.

The shank adapter is mainly used for mining operations, and high-quality alloy steel is selected as the raw material, and the whole is carburized. Use special CNC machine tool processing equipment and processing technology to ensure the quality of the tail details, internal water holes and side water holes. The shank is uniformly heat-treated and scientifically straightened with precision instruments to ensure the shank's straightness and anti-irritability. The shank is used to transfer the energy of the drilling rig and the drill pipe. One end is connected to the drilling rig and the other end is connected to the drill pipe. Therefore, the energy of the drilling rig can be transmitted to the drill bit and finally achieve the purpose of tunneling.

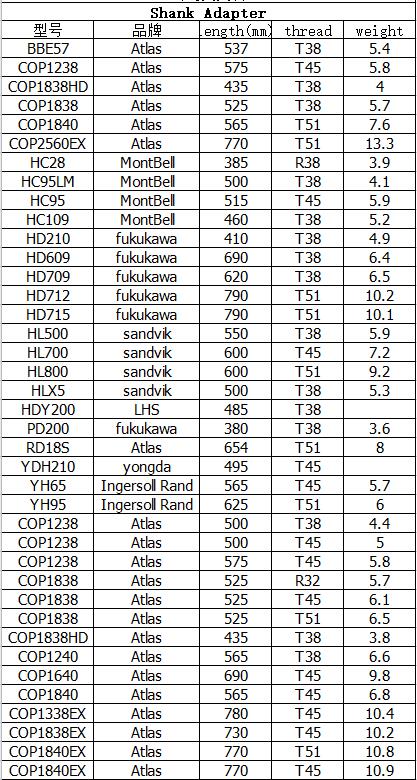

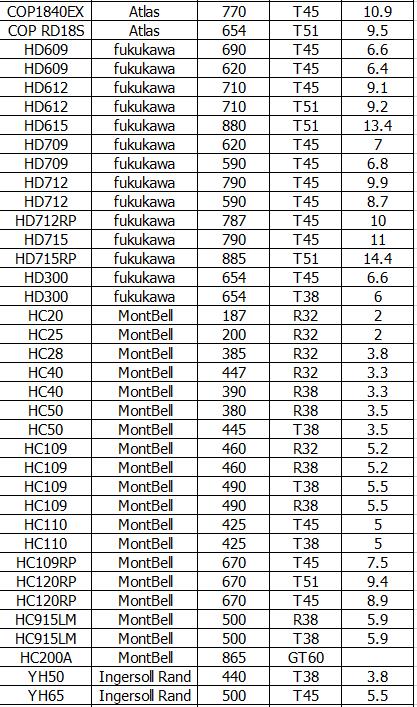

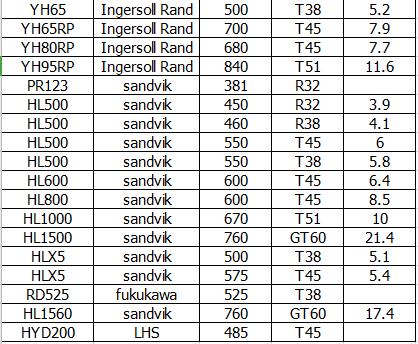

Code No.: COP1840/COP2560EX/HD712/HD715/HL800/RD18S/HY95

Thread Type: T51

Length: 565/770/790/600/654/625mm

Rock Drill Manufacturer: FUKUKAWA/MontBell/sandvik/Ingersoll Rand

COP1840-T51-565:

COP2560EX-T51-770:

HD712-T51-790:

HD800-T51-600:

RD18S-T51-654:

YH95-T51-625:

Shank Adapter Packaging:

Specification: