Essential Usage Guidelines for Drill Rods on Drill Rigs

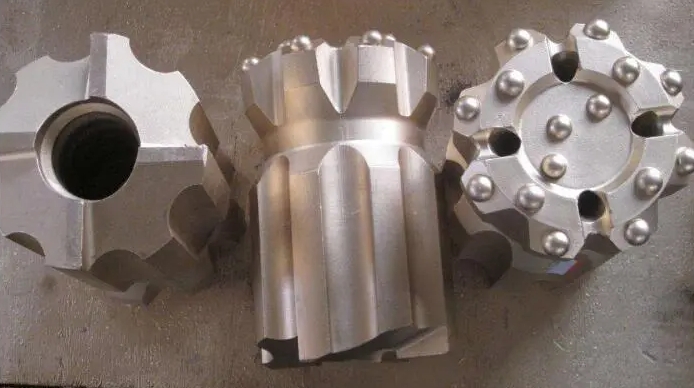

Drill rods mounted on drill rigs have become indispensable in numerous industries today, yet many individuals may still be unfamiliar with them. Before using a drill rod, it's crucial to recognize that it is a commonly employed tool in contemporary geological exploration, renowned for its outstanding performance. However, some might not understand or know why it is necessary to pair a drill rod with either a diamond drill bit or a PDC (Polycrystalline Diamond Compact) drill bit.

Drill rods, available in a wide array of specifications, serve a broad range of purposes. They can be tailored according to the customer’s preferences, and in most cases, flat mouth designs are implemented on smaller diameter geological drill rods. As the diameter of these rods increases, so do the torque and depth capabilities. Custom production can also be arranged to meet specific customer needs.

The application areas for drill rods are extensive, encompassing bridge construction, tunnels, railways, highways, hydraulic engineering, building projects, mining, and more. One of the key advantages of drill rods is their construction from special alloy steel pipes, granting them exceptional hardness. Following surface hardening, the use of sophisticated automatic processing equipment ensures high precision in the manufacturing of each product. Moreover, thanks to superior manufacturing techniques, these rods meet certain standards during use, boasting significant curvature which ensures smooth operation and a relatively high resistance to bending moments. This is why drill rods are often the preferred choice.

Drill rods are designed for use in all seasons. Nevertheless, during winter, regular maintenance is advised to mitigate the impact of air humidity and environmental changes on product quality. Maintenance should account for air moisture, and it's recommended to perform routine dust prevention and rust-proof oil treatments. Additionally, ensuring proper connection in a well-ventilated area is important, and any worn or damaged seals should be replaced promptly.

When using drill rods, it’s important to note that although they can be employed in various settings, long-term usage in highly corrosive environments necessitates timely cleaning of the surface to remove any corrosion layer to prevent damage. For storage, it's advised to keep the rods in a dry environment, supported at several points to ensure better storage outcomes and, to an extent, serve as regular maintenance.

By adhering to these guidelines, users can extend the lifespan and maintain the performance of their drill rods. It is hoped that these points will become common knowledge among those utilizing drill rod systems on drill rigs.