- Gaea

- China

- 5-25天

Safely and high-efficiently breaking rock is of practical significance.

Gas Cracking Filling Machine Non-detonating Blasting Rock Drill Blasting Contractors

Related reports:

Development of CO2 blasting technology;

Exploration and analysis of construction technology of carbon dioxide rock demolition system;

What is carbon dioxide(CO2) rock cracking(rock demolition system);

Phase change cracking of liquid carbon dioxide is a physical cracking process. By chemically heating liquid carbon dioxide, the pressure increases sharply to 20MPa~60MPa. The high-pressure liquid carbon dioxide breaks through the constant pressure shearing plate and quickly transforms into gaseous state. The volume expands more than 600 times and is released instantly. The gas expansion can crack the coal around the borehole; the volume expansion process of liquid carbon dioxide will absorb a large amount of heat, which can effectively reduce the temperature of the coal within the cracking range, which is beneficial to inhibit spontaneous combustion of the coal seam; the phase change cracking of liquid carbon dioxide uses low pressure Start-up (9v) is safer than traditional blasting and does not require gun inspection. People can enter after blasting to achieve continuous work.

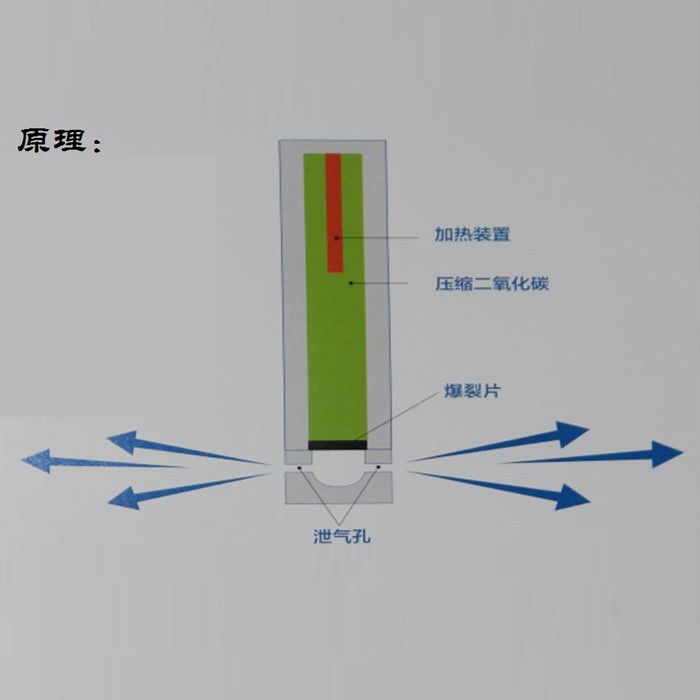

Principle of carbon dioxide explosion(CO2 rock blasting system):

Carbon dioxide gas can be converted into a liquid state under a certain high pressure. The liquid carbon dioxide is compressed into a cylindrical container (blasting tube) through a high-pressure pump, the rupture disc, heat conduction rod and sealing ring are installed, and the alloy cap is tightened to complete the pre-blasting process. Preparation. Bring the blasting tube, safety cloud detonator and power cord to the blasting site, insert the blasting tube into the drill hole and fix it, and connect the detonator power supply. When the micro-current passes through the high thermal conductivity rod, high temperature is generated to break down the safety film, instantly vaporizing the liquid carbon dioxide, and rapidly expanding to generate a high-pressure shock wave that causes the pressure relief valve to automatically open. The blasted items or accumulations are rapidly pushed outward by the geometric equivalent shock wave. , the whole process from detonation to end only takes 0.4 milliseconds, and it operates at low temperature, does not merge with the liquid and gas in the surrounding environment, does not produce any harmful gases, does not generate arcs and sparks, and is not affected by high temperature, high heat, and high humidity. , the influence of high cold. It has a diluting effect on gas during underground blasting, without shock and dust. Carbon dioxide is an inert gas, non-flammable and explosive substance. The explosion process is a process of volume expansion. It is a physical work rather than a chemical reaction.

Advantages of CO2 rock blasting system:

1. It has intrinsic safety characteristics. It is very safe in terms of storage, transportation, carrying, use and recycling. The host machine is separated from the blasting equipment, so the time from filling to the end of blasting is short. The filling of liquid carbon dioxide only takes 1-3 minutes, and it only takes 4 milliseconds from detonation to completion. There are no dumb guns during the implementation process and no inspection is required. The safety warning distance is short and there are no safety hazards. The blasting tube is easy to recycle and can be used continuously.

2. It can perform both directional blasting and delayed control, especially in special environments, such as residential areas, tunnels, subways, underground and other environments. There will be no destructive vibrations and short waves during the implementation process, and no destructive impact on the surrounding environment.

3. No pyrotechnics library is required, management is simple, operation is easy to learn, there are few operators, and no professional staff is required.

4. Its performance is more outstanding when used in mines, whether it is high gas mines, mines with rock pressure, mines with complex hydrogeological conditions, or mines prone to spontaneous combustion.

5. The sources of materials are abundant and can be obtained locally. Liquid carbon dioxide is available in chemical plants and filling stations. Improve efficacy, increase benefits, and reduce costs. Reduce complicated approval review procedures and management restrictions. Everything is non-explosive before being injected with carbon dioxide.

7. In order to obtain a larger equivalent of power, the blasting tubes can be used in parallel according to the site conditions.

8. Environmental protection: Directional energy discharge does not cause damage to the surrounding environment, does not produce harmful gases such as carbon monoxide and nitrogen oxides, can better improve the working environment, and is beneficial to the health of workers.

9. Convenience: By changing the filling amount of CO2 (carbon dioxide) and replacing different types of constant energy pressure relief sheets and heating activators, the working pressure of the expansion system can be controlled to adapt to different working environments.

10. Economical: The entire system can be used repeatedly and the cost of use is low.

11. Safety: The processes of assembly, filling and transportation are safe and reliable. Compared with explosive blasting, it can completely eliminate the accident of dumb cannon collapse.

12. Fast: The assembly and filling operations are simple, and the blasting preparation time is short, which can greatly improve work efficiency and mass production.

Efficient and safe rock demolition is of paramount importance in many engineering projects, but traditional methods such as explosive blasting can have undesirable side effects. Non-explosive alternatives such as demolition agents and rock breaking machines are often time-consuming and may not be suitable for all situations. To address these challenges, a novel liquid carbon dioxide rock breaking technology has been developed and a specialized device designed for its use. This cutting-edge technique has been rigorously tested for effectiveness, safety, and efficiency through shock pressure testing, vibration site testing, and field rock breaking experiments. The results demonstrate that the carbon dioxide rock breaking system is a promising alternative to traditional methods for achieving precise and controlled rock demolition.

The experimental results show that the duration of the monitoring shock pressure is around 1500 μs. The shock pressure signal of liquid carbon dioxide tube breaking in free condition contains four stages, namely, increasing exponentially, decreasing oscillatory, stabilization, and negative pressure stage. As pressure sensor is set at 850 mm from the test tube radially, the shock pressure monitored increases to the maximum value of 115.7 kPa within 6 μs. During the liquid carbon dioxide rock breaking, the vertical component of the peak particle velocity of vibration is 173 mm/s, 85 mm/s and 35 mm/s along distance at 1.5 m, 2.5 m and 3.5 m from the tube, respectively. The Fourier power spectra results show that about 85% energy distributes at 6–60 Hz.

The use of liquid carbon dioxide for rock demolition offers significant advantages over traditional methods. Unlike explosive blasting, which can generate significant vibration and shock waves that may not meet mainstream safety criteria, the vibration caused by the CO2 gas expansion fracturing is minimal. This makes it a safer option for rock demolition in mining, quarrying, and building demolition applications.

Another advantage of the CO2 gas expansion fracturing technology is that it is non-explosive, meaning it does not generate shock waves, vibration waves, or blasting waves. Instead, the gas expansion is generated by a physical volume change, resulting in a controlled and precise fracturing of the rock without the need for explosives.

In addition to its safety and precision, the CO2 gas expansion fracturing technology is also highly efficient. It has been successfully used in rock excavation at a metro station construction site, demonstrating its effectiveness in real-world applications. Compared to traditional non-explosive techniques, this innovative technology offers a faster and more efficient method for rock breaking.

Overall, the liquid carbon dioxide rock-breaking technology represents a significant advancement in the field of rock demolition and provides a safer, more precise, and efficient alternative to traditional methods. Its application has the potential to revolutionize mining, quarrying, and building demolition industries, and its benefits will continue to be explored as the technology advances.

No impact wave

No vibration Wave

No blasting wave

Data of gas expansion

Scope of application:

Any industry that uses traditional explosives can be applied, and special areas or places in non-civil explosion areas can better reflect its superior characteristics.

1. Mining industry: mining of open pit mines and mining, mining, roofing and coal bunkers can be applied. Such as the elimination of the working surface, eliminating the impact of ground pressure, Shimen Jie coal, roadway bottom drum treatment, treatment of coal seam faults, dredging coal bunkers.

2. Emergency rescue and rescue: road clearing, treatment of dammed lakes, removal of landslides, flood discharge, and reinforcement of dams. It is also an indispensable tool for mine rescue teams.

3. Subways and tunnels and municipal works: blasting and excavation of tough rocks, directional blasting of urban concrete buildings, excavation of road trenches, etc.

4, cement, steel, electricity and other industries: preheaters, rotary kiln, furnace kiln steel slag and other equipment and facilities clearing. Agglomeration treatment of garbage burning furnace in urban thermal power plants. The tower chassis reinforcement of mountain high-voltage lines.

5. Geological exploration: field drilling sampling, various stone and mineral mining and cutting.

6, high cold area: icebreaking, snow peak blasting, loose operation of various powdery blocks.

7. Underwater engineering: submarine cable and pipeline trench excavation, submarine drilling and blasting, etc.

Gas filling machine

Gas filling machine is consist of variable-frequency motor control and hydraulic control,which can fill 500L liquid CO2 in an hour,be able to fill 5pcs 5KG cylinders in2 minutes,and filling pressure can reach to 50Mpa.

FAQ:

1.How is the carbon dioxide gas supplied to the CO2 rock demolition system?

Answer: The CO2 gas can be supplied to the system through cylinders or tanks specifically designed for the safe storage and delivery of carbon dioxide.

2.What are the typical sizes and specifications of a CO2 rock demolition system?

Answer: CO2 rock demolition systems come in various sizes and specifications to accommodate different project requirements, including the number of holes, pressure levels, and flow rates.

3.Are there specific temperature or pressure requirements for the CO2 rock demolition system to function effectively?

Answer: The CO2 rock demolition system typically operates within specific temperature and pressure ranges to ensure optimal performance, which can vary depending on the equipment model.

Gas filling video: