High-Pressure Down-the-Hole Drill Bit Selection Guide

In high-pressure down-the-hole (DTH) drilling projects, speed and efficiency are the ultimate goals. The most important “weapon” to achieve them? A high-quality, high-performance DTH drill bit. Choose the right bit, and you get twice the results with half the effort. Choose the wrong one, and you risk wasting time, money, and energy.

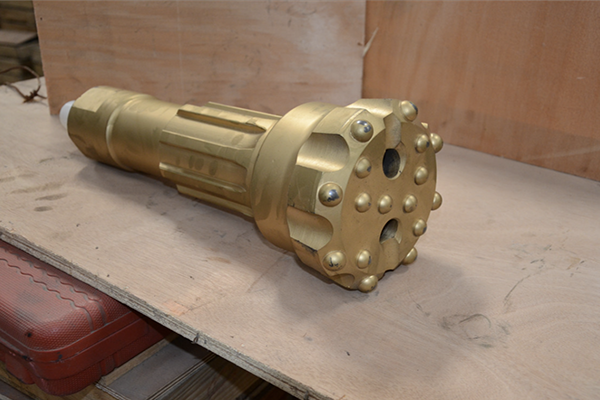

This guide focuses on one of the most critical factors in drill bit performance—the design of the bit face. Different rocks and working conditions call for different “faces,” each with its own strengths and weaknesses.

Why the Bit Face Matters

The face design of a DTH drill bit directly affects drilling speed, borehole quality (especially straightness), bit life, and overall productivity. While many factors influence these outcomes, the bit face is like the “expression” of the drill bit—it determines how it will perform in the field.

Currently, high-pressure DTH drill bits commonly use four main face designs, each with its own “personality” and best-use scenario.

1. Convex Face – The “Assault Specialist”

Features: A raised, convex face.

Advantages: Maintains a high penetration rate in hard to very hard and highly abrasive rock, with impact force concentrated in the center.

Limitations: Borehole straightness is generally lower.

Best For: Projects that prioritize drilling speed over hole straightness in hard, abrasive formations.

2. Flat Face – The “All-Round Warrior”

Features: A completely flat face.

Advantages: Strongest and most durable structure with excellent impact resistance.

Best For: Very hard and hard rock drilling, as well as medium-hard to soft rock where hole straightness is not a top priority. A dependable, highly reliable choice.

3. Concave Face – The “Precision Star Player”

Features: A shallow, cone-shaped depression in the center.

Advantages:

Accurate Guidance: The recessed center creates a mild “nucleation” effect, improving centering and resulting in better hole straightness.

Efficient Cuttings Removal: Excellent flushing and chip removal performance.

Balanced Performance: Delivers good straightness, high penetration rate, and effective cuttings clearance.

Market Position: This design’s well-rounded performance makes it one of the most widely used bit types in today’s high-pressure DTH drilling market.

Best For: Applications that require both high hole straightness and fast drilling in various formations, especially medium-hard rock.

4. Deep Concave Center – The “Soft-Rock Guiding Expert”

Features: A pronounced, deep depression in the center.

Advantages: Enhances the nucleation effect, providing excellent hole straightness in deep-hole drilling.

Limitations: Weaker structural strength compared to other designs.

Best For: Deep-hole drilling in soft to medium-hard rock where hole straightness is critical. Not recommended for hard rock.

Matching the Bit to the Job

There’s no such thing as a universal drill bit. In high-pressure DTH drilling, the best results come from selecting a bit face based on:

Rock hardness and abrasiveness

Requirements for hole straightness

Target drilling depth

Efficiency expectations

Knowing the strengths and trade-offs of these four face types lets you choose the right “face” for your project—turning your drilling operation into a precision, high-efficiency performance. When you match the bit to the battlefield, you truly double your efficiency.