How critical is a dedicated aluminum tube for liquid‑oxygen rock (LOX) blasting?

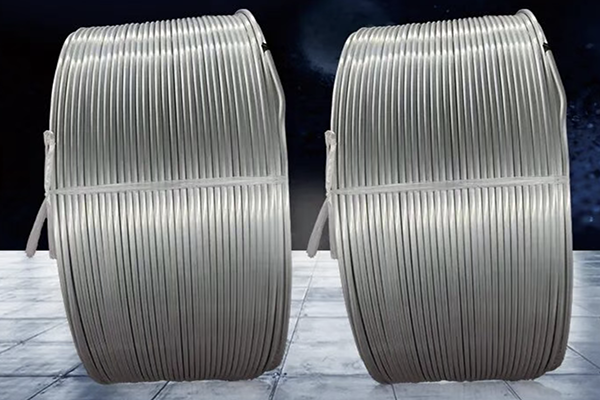

When carrying out LOX rock blasting, ordinary tubing cannot serve the system because of liquid oxygen’s extremely low temperature. That’s why dedicated aluminum tubing for LOX rock blasting is required. Such tubing retains stable performance at cryogenic temperatures, reliably conveys LOX and withstands operating pressure. It is the core conveyance and storage element of a LOX rock blasting system and one of its key tools.

A qualified LOX rock blasting aluminum tube should be made from high‑quality aluminum alloy with good thermal conductivity, corrosion resistance, stable mechanical properties, and sufficient pressure and temperature resistance. It should tolerate bending and flaring operations to suit different field configurations.

The tubing’s role in ensuring LOX transfer stability and safety is mainly twofold:

Safe storage and transport of LOX: its material resists the extreme cold of LOX, preventing brittle fracture during transport or storage that could lead to leaks, thereby protecting the transfer process and preserving LOX integrity.

Support for blasting operations: owing to the tube’s strength and sealing performance, it can withstand pressures generated during blasting. After LOX is injected and mixed with fuel, the resulting combustion/explosion forces are transmitted stably through the aluminum tubing to produce the desired rock‑breaking effect.

In short, LOX‑specific aluminum tubing—because of its unique physical properties—serves as the storage/transport channel for LOX and plays a critical role in the blasting process.

How to choose mining blasting firing line (firing cable): a concise guide

Mining blasting firing lines are specialized interconnection cables for initiating blasts. They feature resistance to cold, high temperature, strong acids and alkalis, and are widely used in mining, tunneling, demolition, and other blasting applications. Because of the special environments in which they operate, selecting an appropriate firing line requires considering multiple factors:

Blasting environment: choose a cable suited to site conditions. For humid environments select good waterproofing; in gas‑ or coal‑dust‑hazardous mines choose cables with appropriate explosion‑resistant properties.

Scale of blasting: select length and cross‑section (or diameter) according to blast scale. Larger blasts generally require thicker and longer firing lines.

Initiation method: different initiation methods require different cable properties. For electric detonators choose cables with good electrical conductivity; for pyrotechnic (non‑electric) initiation choose lines that tolerate high temperatures and abrasion.

Storage and operating conditions: select cables that suit the storage and usage environment (high/low temperature, humidity, corrosive conditions).

Safety features: choose firing lines that meet safety standards (fire‑resistant, explosion‑resistant, anti‑static as required).

Cost‑effectiveness: within the required performance parameters, choose options with a reasonable price and long service life.

Common specifications include diameters such as 0.52 mm and 0.62 mm; core materials typically include pure copper, tinned/gavanized copper, or steel wire. Combine the above considerations with specific blasting needs to choose the right specification, and always operate the firing line strictly according to regulations to ensure personnel safety.