How to match the four main types of coupling sleeves to your drilling needs

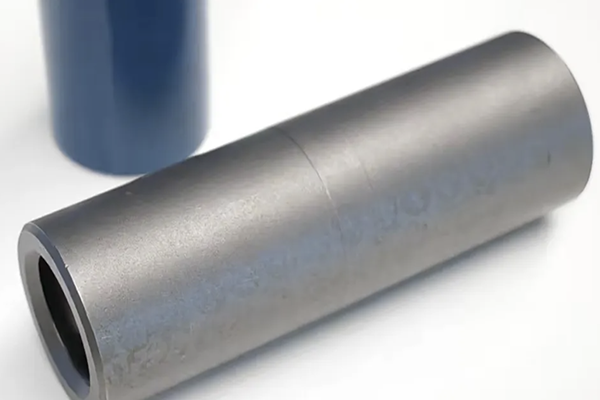

In tunnel and mining engineering, a reliable drill‑string system is essential for productive drilling, and the coupling sleeve is the system’s critical hinge. Acting like a precision joint, the coupling sleeve links different drill components; its performance directly affects drilling efficiency, equipment life and project cost. Based on design and application differences, coupling sleeves are typically divided into four types — full‑bridge, half‑bridge, reducing (step) and equal‑diameter — each with distinct strengths suited to different working conditions.

Full‑bridge coupling sleeve: the heavy‑duty connector for large projects Full‑bridge coupling sleeves are usually made from high‑strength alloy steel that has undergone special heat treatment (quenching), giving them outstanding strength and toughness to withstand the high impact forces and torque generated during drilling. Their structural hallmark is a trapezoidal thread design, which ensures tight engagement for stable transmission of power and torque while remaining relatively easy to disassemble—improving on‑site efficiency. Full‑bridge sleeves are particularly well suited to rigs with independent rotation units and are commonly used in open‑pit mining, tunnel headings and other large‑scale operations that demand high connection strength and reliability.

Half‑bridge coupling sleeve: the underground torque specialist Half‑bridge coupling sleeves play an important role in underground mining and anchoring works. They require very strict material standards—high‑strength alloy steels with tight control over purity and microstructure. Their distinctive bridged frame design provides superior resistance to high torque, making them ideal partners for rigs using wave‑form (corrugated) or stepped threads. In the variable and torque‑intensive environment of underground operations, half‑bridge sleeves offer reliable performance for efficient advancement and safe anchoring.

Reducing (step) coupling sleeve: the diameter‑conversion bridge When drilling calls for joining components of different diameters, the reducing coupling sleeve is the solution. Typically manufactured from medium‑carbon or alloy steel, these sleeves are engineered specifically to connect rods of differing diameters. Their straightforward design makes installation and removal fast and simple, saving time and labor. Whether for temporary diameter adjustments on small tunnel jobs or for special‑spec connections on large projects, reducing sleeves quickly establish the required link to keep drilling progressing.

Equal‑diameter coupling sleeve: the universal reliable link Equal‑diameter coupling sleeves, also made from medium‑carbon or alloy steel, are used to join rods of the same diameter. Compact and space‑efficient, they provide robust connections across a wide range of tunneling and mining scenarios where like‑sized rod sections must be joined. Their ease of installation and removal helps improve workflow and on‑site productivity.

Summary Selecting the right coupling sleeve depends on project scale, drilling method and the expected torque/impact conditions. Full‑bridge sleeves suit heavy, high‑torque applications; half‑bridge sleeves excel in torque‑intensive underground work; reducing sleeves solve diameter‑mismatch needs with fast field assembly; and equal‑diameter sleeves offer a compact, general‑purpose connection for like‑sized rods.