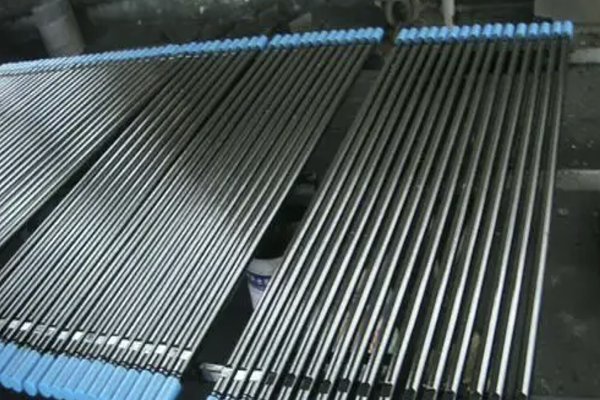

Proper Use and Maintenance Tips for Drill Rods

Drill rods are core components of rock‑drilling and demolition equipment, and correct use and maintenance directly affect productivity, operating cost, and equipment life. Mastering proper operating and care procedures reduces rod wear and improves safety.

I. Correct use

Match the equipment Always select rods whose specifications and models match the drill or breaker precisely. Mismatched rods can lead to uneven loading, breakage, or accelerated wear. Never use undersized rods on high‑power machines or employ rods beyond their rated application for heavy work.

Follow standard operating procedures Before starting work, inspect the rod‑to‑machine connection—check the shank, shoulder, and other joint components for looseness or deformation, and ensure bolts and fasteners are properly tightened. Start the machine unloaded; after stable operation is confirmed, engage the workface. Keep the rod perpendicular to the work surface; avoid off‑center or angled impacts that can bend or break the rod. Control impact force and frequency and avoid prolonged overload. If you hear unusual noises or detect abnormal vibration, stop immediately and inspect.

Manage the working environment Clear debris from the workface—loose rock and foreign objects can damage the rod during impact. After operating in high‑temperature conditions, avoid immediate cooling with cold water to prevent thermal shock and possible material embrittlement.

II. Routine maintenance

Regular cleaning and inspection After each shift, remove dirt, rock fragments, oil, and other contaminants from the rod surface, paying special attention to the shank, bit threads, and locating faces. Inspect for cracks, deformation, or excessive wear. If visible cracks appear or bit wear exceeds allowable limits, replace the rod—do not continue using a compromised rod.

Proper lubrication and rust prevention Regularly lubricate threaded joints and mating surfaces with a suitable specialty lubricant to form a protective film, reduce frictional wear, and prevent thread corrosion and seizure. For long‑term storage, clean rods thoroughly, coat them with rust‑preventive oil, and keep them in a dry, ventilated storage area to avoid moisture‑induced corrosion.

Correct storage practices Store rods either vertically suspended or on horizontal racks; avoid stacking them directly on the ground to prevent bending or deformation. Segregate and label different specifications and models to prevent mixing.

III. Common faults: prevention and remedies

Breakage Prevention focuses on avoiding off‑center hits, overload, and using the correct rod for the machine. If a rod breaks, stop the machine, replace the rod, and inspect the host equipment for abnormal impact forces or other faults before resuming work.

Excessive wear Control operating durations, monitor wear regularly, and replace over‑worn rods promptly. Improve operating methods to minimize direct impacts with hard debris.

Thread seizure Clean and lubricate threads before and after each use. If thread seizure occurs, apply a rust remover or penetrating oil and loosen the connection slowly; do not force or strike the joint violently, which can damage the threads.

Consistent, proper use and systematic maintenance are key to extending drill rod life. Operators should develop disciplined operating habits and regular care routines; attention to these details reduces consumable costs and enhances overall equipment efficiency.