Step-by-Step Guide to Using O2 Rock Blasting Systems Effectively

New technology: O2 rock demolition system

Link:

Using the O2 rock blasting system requires precision and adherence to strict safety measures. This process involves more than just detonating explosives. You must ensure personnel and equipment are cleared from the area, establish exclusion zones, and provide warning signals to avoid accidents. Calculating blast hole parameters prevents fly rock and protects surrounding areas. Comprehensive training for operators is essential, as it builds awareness of risks and ensures proper procedures are followed. By following these steps, you can achieve safe, efficient, and effective blasting results.

Key Takeaways

Always focus on safety by checking for risks before blasting. Find dangers to keep people and tools safe.

Train workers well so they know the risks and follow rules. This helps prevent accidents from happening.

Use the O2 rock blasting system because it saves money. It costs about $1 per cubic meter, great for big jobs.

Check the area after blasting to see how it went. Look for leftover dangers to stay safe and do better next time.

The O2 system is good for the environment. Its low pollution design helps protect nature and supports green practices.

Understanding the O2 Rock Blasting System

What Is the O2 Rock Blasting System?

The O2 rock blasting system is an innovative solution designed for efficient and safe rock fragmentation. It uses High-Energy Emulsion Agents (HEEA) to generate controlled explosions that break apart rock formations. This system stands out for its ability to deliver powerful results while minimizing risks to operators and the environment.

One of its key advantages is its cost-effective operation, with an average blasting cost of just $1 per cubic meter. This makes it an economical choice for large-scale projects. Additionally, the system prioritizes safety by producing controlled shock waves and non-toxic emissions, ensuring it can be used in sensitive environments. Its environmentally friendly design further supports sustainable practices, making it suitable for mining, quarrying, and urban demolition.

Key Features and Applications

The O2 rock blasting system offers several technical features that enhance its performance. These include high detonation pressure, efficient combustion heat, and optimized gas production components. These parameters ensure effective rock fragmentation while reducing environmental impact.

This system is highly versatile, making it ideal for various applications. You can use it in mining operations to extract valuable minerals or in quarries to produce construction materials. Its low shock wave emissions also make it suitable for urban demolition projects, where minimizing disruption is critical. By leveraging these features, you can achieve precise and efficient results across a wide range of scenarios.

Step-by-Step Guide to Safe Operation

Preparation and Risk Assessment

Effective preparation begins with a thorough risk assessment. You must evaluate the blasting site to identify potential hazards and ensure the safety of personnel and equipment. Start by analyzing the terrain, geological conditions, and proximity to sensitive areas like residential zones or water bodies. This helps you determine the best approach for using the O2 rock blasting system.

Risk assessment involves reviewing historical data to anticipate challenges. For example:

A global retail company avoided losses during a natural disaster by diversifying suppliers after identifying risks in their supply chain.

A financial institution reduced phishing incidents by 80% after implementing cybersecurity training and measures.

Additionally, historical risk data uncovers trends and critical events that could impact operations. It answers questions about the severity of risks and helps assess preparedness against previously identified threats. By leveraging this information, you can create a safer blasting environment and minimize disruptions during open pit blasting.

Setting Up the System

Setting up the O2 rock blasting system requires precision and attention to detail. Begin by inspecting all components to ensure they are in optimal condition. Position the system at the designated blast site, adhering to the parameters established during the risk assessment phase. Proper alignment and calibration are crucial for achieving controlled energy release and effective rock fragmentation.

Efficiency studies highlight key practices for setup:

Prewarming resources before operation improves performance by reducing delays during system startup.

Identifying bottlenecks during the design phase ensures stability under production loads.

Continuous monitoring of system performance helps optimize operations and prevent resource-heavy processes.

These practices enhance the reliability of the rock breaking system, ensuring smooth execution during open pit blasting. Always double-check connections and verify that all safety measures are in place before proceeding.

Operating the System Safely

Safety is paramount when operating the O2 rock blasting system. You must follow established protocols to protect personnel and equipment. Begin by clearing the blast zone and establishing exclusion areas. Use warning signals to alert nearby workers and ensure everyone is at a safe distance.

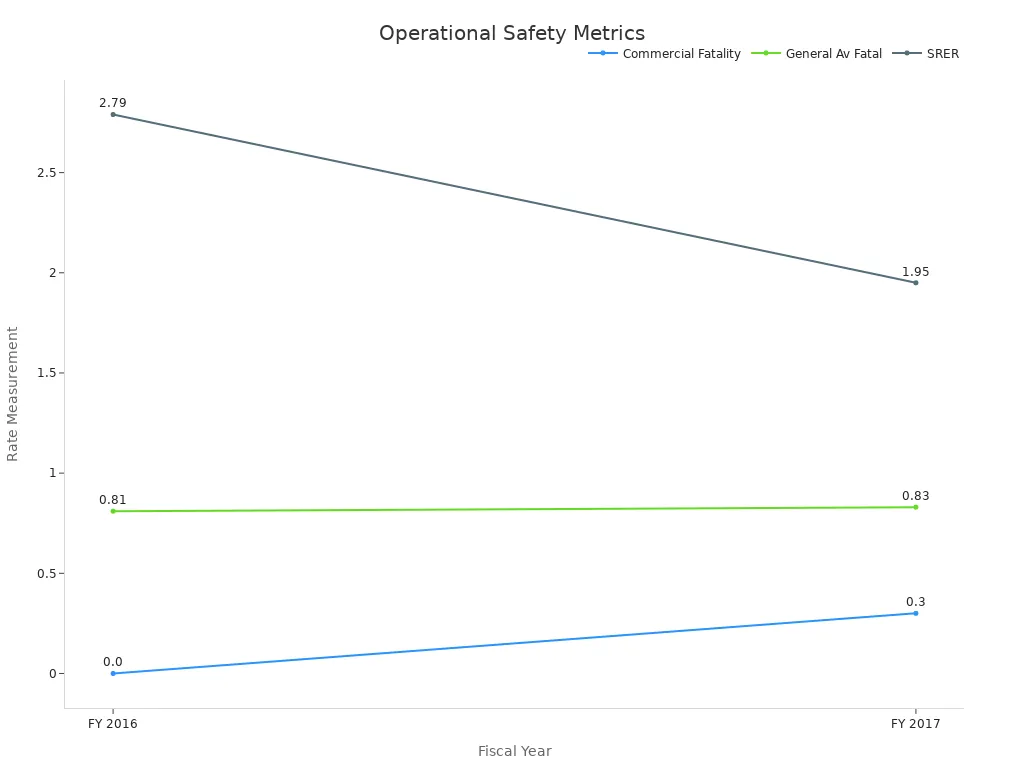

Operational safety metrics provide valuable insights into minimizing risks:

These metrics emphasize the importance of adhering to safety protocols. Monitor the system during operation to detect anomalies and prevent errors. After the blast, conduct a thorough inspection to ensure the area is secure and free from hazards. This approach guarantees safe and efficient use of the rock breaking system in open pit mining projects.

Post-Operation Inspections

After completing an open pit blasting operation, conducting thorough post-operation inspections ensures safety and operational success. You must evaluate the blast site to confirm that all hazards have been mitigated and the area is secure for further activities. This step is critical for maintaining controlled energy release and preventing accidents.

Key Steps in Post-Operation Inspections:

Assess Blast Results

Examine the fragmentation of the rock to ensure the desired outcome was achieved. Look for signs of overblasting or underblasting, which could indicate issues with the setup or execution. Proper evaluation helps refine future operations.Check for Residual Hazards

Inspect the blast zone for unexploded materials or unstable rock formations. These hazards pose risks to personnel and equipment. Use specialized tools to detect and safely remove any residual explosives.Verify Equipment Condition

Inspect all components of the O2 rock blasting system for wear or damage. Pay close attention to critical parts like detonation devices and gas production components. Regular maintenance extends the system's lifespan and ensures reliable performance in open pit mining projects.Document Findings

Record all observations and measurements from the inspection. Include details about the blast results, equipment condition, and any hazards identified. This documentation serves as a valuable resource for improving future open pit blasting operations.

Tips for Effective Inspections:

Pro Tip: Use a checklist to streamline the inspection process. Include items like blast results, equipment condition, and site safety. This ensures no critical aspect is overlooked.

Common Challenges and Solutions:

By following these steps, you can ensure the safety of the blast site and optimize the efficiency of your operations. Post-operation inspections are not just a safety measure; they are an opportunity to learn and improve your approach to open pit blasting.

Safety Precautions and Best Practices

Ensuring safety during open pit blasting operations is critical for protecting workers, equipment, and the environment. Following best practices and adhering to safety protocols minimizes risks and enhances operational efficiency. This section outlines essential safety measures, including the use of personal protective equipment (PPE), proper handling and storage guidelines, and effective emergency procedures.

Personal Protective Equipment (PPE)

Wearing the right PPE is your first line of defense against workplace hazards during open pit blasting. Properly selected and maintained equipment can significantly reduce the risk of injuries. You should always ensure that workers are equipped with the following:

Respiratory Protection: Use respirators, such as SCBAs or CBRN respirators, to protect against harmful particulates and gases. Studies show that SCBAs reduce particulate matter concentrations by 95.3% in standard environments, while CBRN respirators achieve reductions of up to 99% in high-exposure conditions.

Eye and Face Protection: Safety goggles and face shields prevent injuries from flying debris and dust.

Hearing Protection: Earplugs or earmuffs protect against the high noise levels generated during blasting.

Body Protection: Flame-resistant clothing and gloves shield workers from heat and potential chemical exposure.

Foot Protection: Steel-toed boots with slip-resistant soles provide stability and protect against falling objects.

Despite the proven effectiveness of PPE, only 12% of employers provide the necessary equipment, and just 23.9% of workers receive training on its proper use. You should prioritize training programs to ensure workers understand how to use PPE correctly. Proper implementation can mitigate over 90% of workplace incidents, making it an indispensable part of your safety strategy.

Tip: Conduct regular PPE inspections to ensure all equipment remains in good condition and complies with safety standards.

Handling and Storage Guidelines

Proper handling and storage of materials and equipment are essential for maintaining safety during open pit blasting. Mishandling can lead to accidents, equipment damage, or environmental hazards. Follow these guidelines to minimize risks:

Storage Conditions: Store explosives and other materials in a cool, dry, and well-ventilated area. Keep them away from heat sources, open flames, and incompatible substances.

Labeling and Organization: Clearly label all materials and organize them systematically to prevent confusion and accidental misuse.

Handling Procedures: Use specialized tools and equipment to handle explosives safely. Avoid direct contact and ensure all personnel follow established protocols.

Data Integrity: Maintain accurate records of material usage and storage conditions. This ensures compliance with safety regulations and enhances operational transparency.

Establishing strict rules for handling and storage not only ensures safety but also improves the efficiency of your operations. Clear instructions for data collection and processing enhance reproducibility and reduce the likelihood of errors.

Note: Regularly review and update your handling and storage procedures to align with industry standards and regulatory requirements.

Emergency Procedures

Even with the best safety measures in place, emergencies can still occur during open pit blasting. Having a well-defined emergency response plan is crucial for minimizing damage and ensuring the safety of all personnel. Your plan should include the following components:

Incident Response: Quickly identify and assess the situation. For example, hydrogen leakage or explosion incidents require rapid action due to hydrogen's high reactivity.

Evacuation Protocols: Establish clear evacuation routes and assembly points. Conduct regular drills to ensure workers are familiar with the procedures.

Communication Systems: Use reliable communication tools to coordinate response efforts and keep all stakeholders informed.

First Aid and Medical Support: Provide immediate medical assistance to injured personnel. Ensure first aid kits and trained responders are readily available.

Studies have shown that systematic emergency planning improves response effectiveness. For instance, using Stochastic Colored Petri Nets (SCPN) to simulate emergency actions enhances understanding of response flow and efficiency. Real-world data from After Action Reviews (AARs) can also help identify areas for improvement.

Pro Tip: Regularly update your emergency response plan based on lessons learned from past incidents and evolving industry standards.

By implementing these safety precautions and best practices, you can create a safer work environment and ensure the success of your open pit mining operations.

Benefits of Using O2 Rock Blasting Systems

Cost-Effectiveness

The O2 rock blasting system offers a highly economical solution for open pit blasting. Its innovative design reduces operational costs by optimizing resource usage and minimizing waste. For instance, the system’s High-Energy Emulsion Agents (HEEA) ensure precise energy release, which eliminates the need for excessive materials. This efficiency translates to significant cost savings, especially in large-scale projects.

By choosing Gaea’s O2 rock blasting systems, you can achieve consistent results without overspending. The system’s low maintenance requirements further enhance its cost-effectiveness, allowing you to allocate resources to other critical areas of your operations. Whether you’re working in open pit mining or urban demolition, this system ensures you get the best value for your investment.

Enhanced Safety

Safety remains a top priority in open pit blasting, and the O2 rock blasting system excels in this area. Its controlled shock waves and non-toxic emissions create a safer environment for workers and nearby communities. Additionally, the system’s advanced design reduces the risk of accidents during operation.

A comparison of safety practices highlights the system’s effectiveness in improving workplace safety:

These statistics emphasize the importance of adopting advanced systems like Gaea’s O2 rock blasting solution. By prioritizing safety, you can protect your team and maintain operational efficiency.

Environmental Advantages

The O2 rock blasting system supports environmental friendliness by minimizing its ecological footprint. Its low-emission design reduces air pollution, making it suitable for sensitive environments. Studies show that transitioning to automated systems in mining operations significantly lowers environmental impacts. For example, the life-cycle assessment (LCA) model reveals a reduction in global warming potential by up to 18%, equivalent to 17.9 kg CO2 per ton of ore. Other benefits include decreases in acidification, eutrophication, and human toxicity.

By using Gaea’s O2 rock blasting systems, you contribute to sustainable practices in open pit mining. This system not only ensures compliance with environmental regulations but also enhances your company’s reputation as a responsible operator.

Improved Efficiency

The O2 rock blasting system significantly enhances efficiency in open pit blasting operations. Its advanced design ensures precise energy release, reducing waste and optimizing resource usage. This precision allows you to achieve better results with fewer materials, saving time and money.

One of the key ways the system improves efficiency is through its High-Energy Emulsion Agents (HEEA). These agents deliver consistent performance, ensuring uniform rock fragmentation. This consistency minimizes the need for rework, allowing you to complete projects faster. For example, in open pit blasting, achieving the desired fragmentation on the first attempt reduces delays and keeps your operations on schedule.

Another factor contributing to efficiency is the system's ease of use. On-site training ensures operators can quickly learn to set up and operate the system. Its user-friendly components require minimal maintenance, reducing downtime. By streamlining these processes, you can focus more on production and less on troubleshooting.

The system also supports open pit mining by reducing environmental impact. Its low-emission design ensures compliance with regulations, avoiding costly fines or project delays. This feature not only benefits the environment but also enhances operational efficiency by maintaining uninterrupted workflows.

Tip: Regularly monitor system performance to identify areas for improvement. Small adjustments can lead to significant gains in efficiency over time.

By leveraging the O2 rock blasting system, you can maximize productivity while minimizing costs and environmental impact. Its innovative features make it an essential tool for achieving efficient and sustainable results in open pit blasting and mining projects.

Using the O2 rock blasting system effectively starts with prioritizing safety and following best practices. Proper preparation, risk assessment, and adherence to safety protocols ensure successful operations while protecting workers and the environment.

Tip: Regular maintenance and operator training improve system performance and reduce risks.

By choosing Gaea’s O2 rock blasting systems, you gain access to reliable, cost-effective, and environmentally friendly solutions. Explore these systems today to enhance your blasting operations and achieve outstanding results.

FAQ

What makes the O2 rock blasting system safer than traditional methods?

The O2 system uses controlled shock waves and non-toxic emissions, reducing risks to workers and the environment. Its advanced design minimizes the chance of accidents during operation. By following safety protocols, you can ensure a secure blasting process.

Can the O2 rock blasting system be used in urban areas?

Yes, the system’s low shock wave emissions make it suitable for urban demolition projects. It minimizes vibrations and noise, ensuring minimal disruption to nearby communities. Always conduct a risk assessment before using it in sensitive locations.

How do I maintain the O2 rock blasting system?

Regularly inspect components like detonation devices and gas production units for wear or damage. Clean and store the system in a dry, ventilated area. Follow the manufacturer’s maintenance schedule to ensure optimal performance and longevity.

Is training required to operate the O2 rock blasting system?

Yes, training is essential. It ensures operators understand the system’s setup, operation, and safety protocols. On-site training programs provided by manufacturers help you and your team achieve safe and efficient results.

What environmental benefits does the O2 system offer?

The system produces low emissions and reduces air pollution, making it eco-friendly. Its efficient energy use minimizes waste, supporting sustainable practices in mining and demolition. By using this system, you contribute to environmental conservation efforts.

Tip: Always check local environmental regulations to ensure compliance when using the system.