Why Do Your DTH Drill Bits Fail After Two Days? Uncovering the Hidden Traps

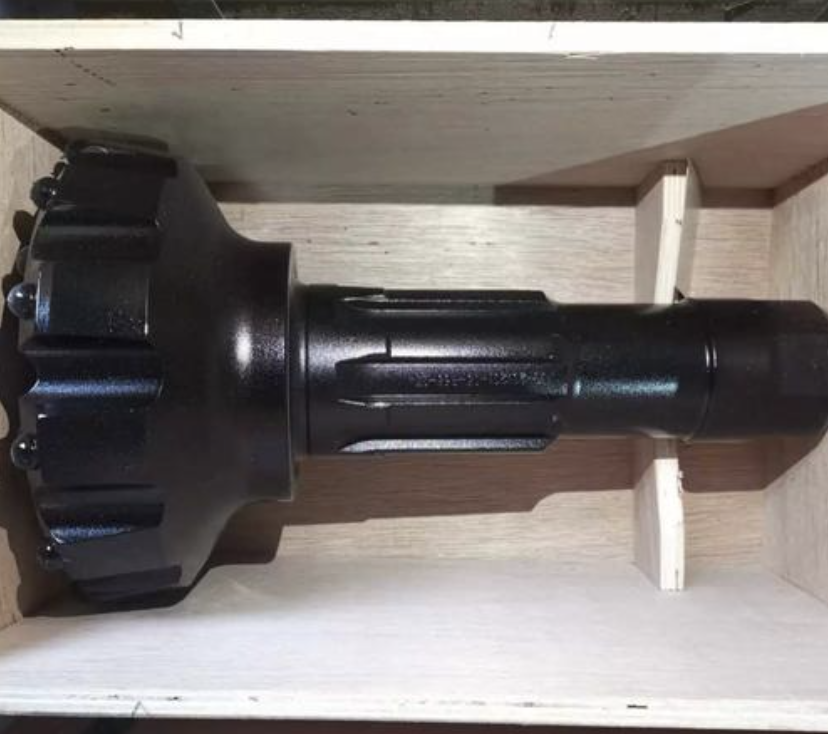

On mine sites and construction projects, down‑the‑hole (DTH) drill bits are true “assault tools” — yet many crews have faced the same frustrating scenario: a freshly fitted DTH bit fragments with a crack or collapse within two days. Beyond delaying schedules, repeated replacements quickly add up in cost. Frequent bit failure is rarely random; more often it’s the result of overlooked “hidden traps” that reflect mistaken judgments about cost and efficiency.

Trap 1 — The Low‑Price Lure: Saving Money, Buying a Pretend Product The most common pitfall is the low‑price trap. On the market, identical‑spec DTH bits can differ in price by twofold or more. Buyers eager to cut costs often pick the cheapest option, not realizing that low price often means corner‑cutting.

The critical load‑bearing parts of a DTH bit are the cutting teeth. Quality bits use high‑strength alloys and precise forging to form sharp, wear‑resistant teeth capable of biting into hard rock. Cheap bits, by contrast, are often cast from inferior alloys or ordinary steel; they may look similar at a glance but have porous microstructure and insufficient hardness. When used against hard formations like granite or basalt, these knockoffs fail immediately — teeth break off or entire teeth shed. The apparent savings vanish once downtime and repeated replacements are counted, and the total loss far exceeds the initial price difference.

Trap 2 — Ignoring Heat Treatment: Making “Brittle Biscuits” Even more insidious than cheap materials is the heat‑treatment trap. If material is the bit’s skeleton, heat treatment is the process that gives that skeleton toughness and strength. Many purchasers focus only on base material specs and overlook heat‑treating — not realizing that an untreated bit is like a brittle biscuit: it looks solid but shatters under load.

High‑quality DTH bits undergo multiple heat‑treatment steps such as quenching and tempering, with precise control of temperature and cooling rates. This produces teeth that combine sufficient hardness to fracture rock with enough toughness to absorb impact. Inferior products that skip key heat‑treatment stages have uneven internal structures and many stress concentration points; under drilling impact they crack from the inside out. The surface may appear intact, but once the drill string is removed the bit is found to be internally fractured and ruined.

Trap 3 — The “Universal Bit” Fallacy: Jack‑of‑All‑Trades, Master of None Beyond material and process faults, belief in a “universal” drill bit causes many problems. When buyers ask if a single bit can handle all geology, they misunderstand DTH design fundamentals. Different formations demand different tooth profiles, alloy types, and flushing/extraction geometries: soft soils need rounded teeth and large cuttings channels for efficient removal; weathered rocks benefit from sharper teeth and mid‑hardness alloys to improve breakage; hard granite requires cutter‑style teeth made of very hard alloys to withstand extreme abrasion. Treating one bit as a cure‑all is like trying to cut rebar with a kitchen knife — either the bit wears out quickly or the teeth shatter. What looks like the convenience of not changing bits actually reduces drilling efficiency and accelerates wear.

How to Avoid These Pits: Ditch Perfectionism, Adopt Risk‑Managed Buying Avoiding rapid DTH bit failure means abandoning the “cheapest or perfect universal” mindset and adopting a “risk‑managed” procurement approach. Chasing zero defects or rock‑bottom price is counterproductive: obsessing over price risks overlooking material flaws, and demanding one‑size‑fits‑all performance sacrifices drilling specificity.

A rational approach is to select bits tailored to the site’s geology, compare prices only among products that meet material and process standards, and accept minor cosmetic imperfections that do not affect core performance. Spend time verifying material specs, checking heat‑treatment records, and matching bit design to ground conditions rather than fixating on whether a product can be cheaper or universally applied.

DTH bit life is not a matter of luck. Bits that fail in two days usually reflect procurement traps rather than mysterious quality issues. By rejecting the temptations of “too cheap” and “one bit fits all,” and by prioritizing material quality, proper heat treatment, and geological matching, you’ll pick truly durable bits and turn procurement dollars into real on‑site efficiency.