- Gaea

- China

- 3000pcs/month

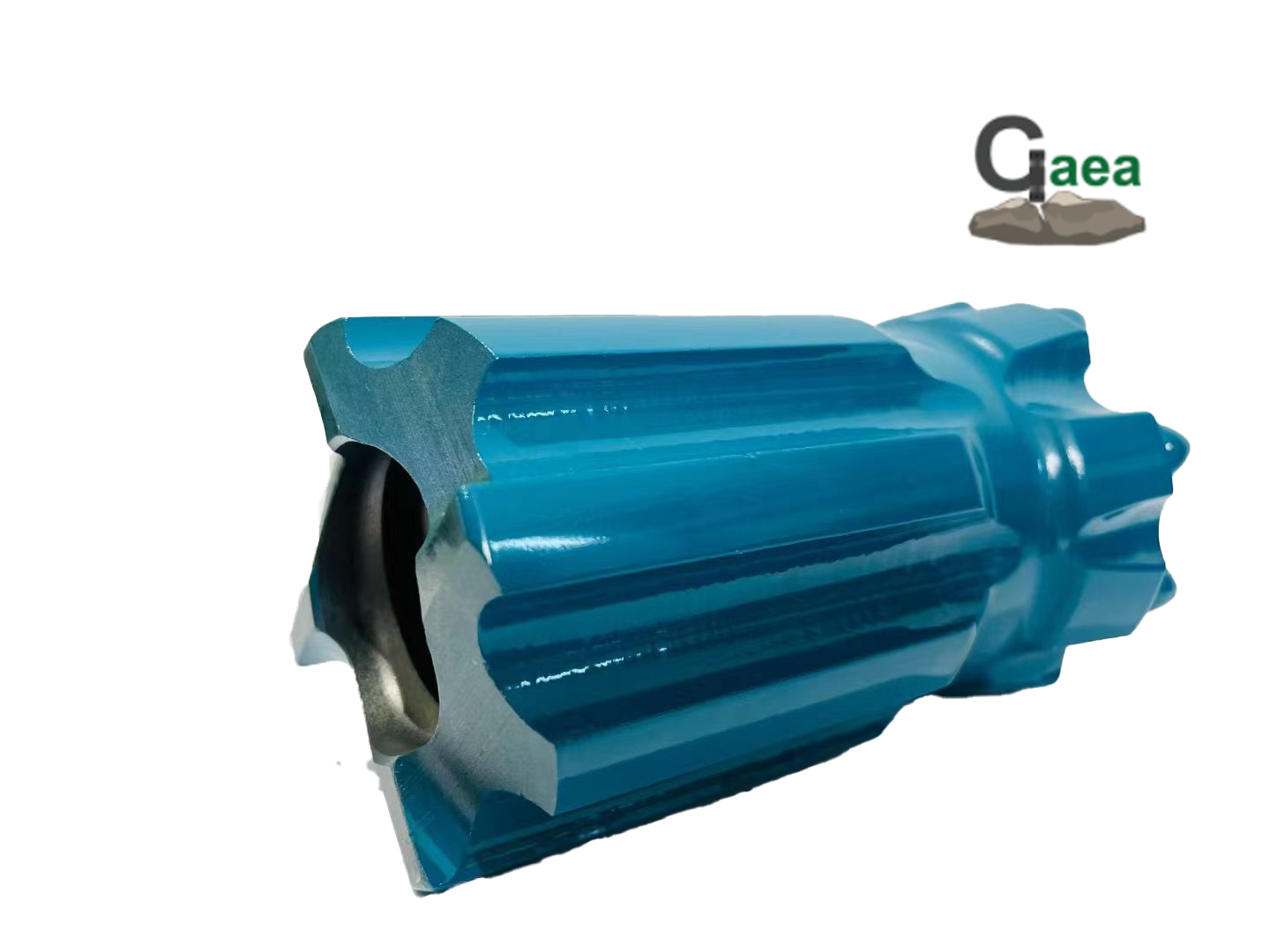

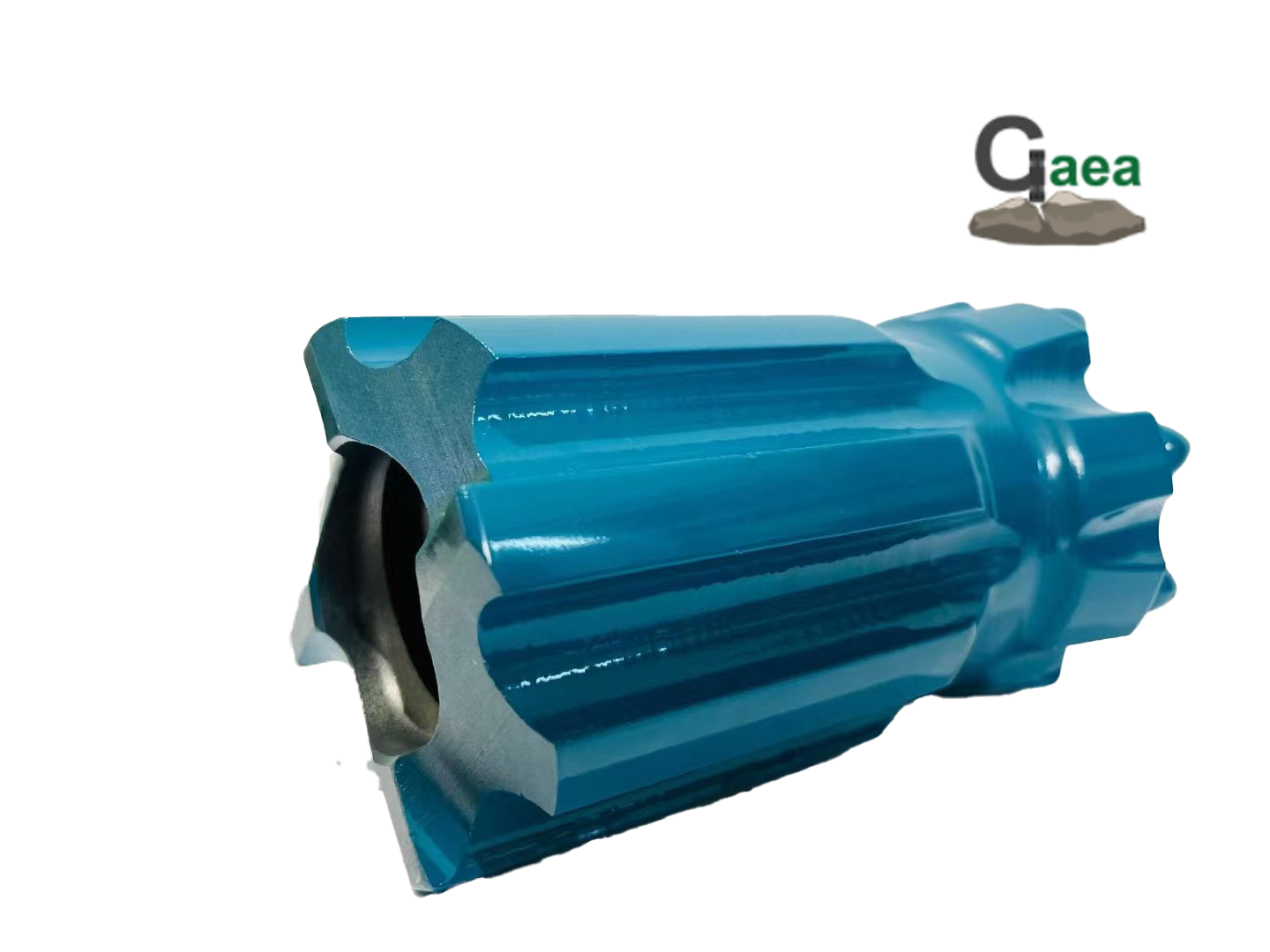

T45-89mm Thread Button Bits: Combining T45 retrac thread compatibility with an 89mm diameter, these bits offer versatility, precision, and efficiency for diverse drilling applications, ensuring durability and consistent high-performance results.

top hammer T45 89mm retrac thread button bits rock drilling tools

Related reports:

Application of drilling bits Carbide Ball Teeth

Instructions for using the drill bit

What processing problems do you need to know about open-ended drills?

Introducing Gaea Rock's T45 89mm Thread Button Bits

Product Overview

At Gaea Rock, we take pride in manufacturing high-quality drilling bits, especially the T45 89mm Thread Button Bits. These top hammer drilling bits, also known as "retrac thread button bits," are engineered for exceptional performance in various drilling applications.

T45 Thread Type

The "T45" designation represents the thread type, ensuring compatibility with a wide range of drilling equipment and machinery. This standardized thread is known for its durability and reliability, making it an industry-favorite for drilling operations.

89mm Diameter

Our T45 89mm Thread Button Bits are specifically designed with an 89mm diameter, a size that strikes a balance between versatility and performance. This diameter allows for efficient drilling while maintaining precision and control over the drilling process.

Key Features

1. Top Hammer Technology

Our T45 89mm Thread Button Bits are optimized for top hammer drilling methods. This technology enables the transfer of maximum energy to the drilling face, resulting in efficient and consistent drilling performance.

2. Retrac Thread Button Bits

The "retrac" feature ensures the drill bit's easy retrieval from the borehole. This design not only saves time during drilling operations but also minimizes downtime and maintenance efforts.

Applications

Gaea Rock's T45 89mm Thread Button Bits are versatile and suitable for a wide range of drilling applications, including:

Quarrying

Mining

Construction

Geotechnical drilling

Well drilling

And more.

Why Choose Gaea Rock's T45 89mm Thread Button Bits?

Precision and Reliability: Our thread button bits are engineered with precision to ensure optimal hole quality and straight drilling.

Durability: Made from high-quality materials, our drill bits are built to withstand challenging drilling conditions and provide long-lasting performance.

Efficiency: With top hammer technology, you can trust our bits to deliver efficient and consistent results.

Global Reach: Gaea Rock products are available worldwide, ensuring you have access to top-tier drilling solutions wherever your project takes you.

Expert Support: Our team of experts is ready to assist you with product selection and technical advice to ensure your drilling operations run smoothly.

In conclusion, Gaea Rock's T45 89mm Thread Button Bits are the reliable choice for drilling professionals who demand high-performance, durability, and precision. With top hammer technology and the convenience of retrac thread button bits, you can trust Gaea Rock to provide the drilling solutions you need for success.

For inquiries, pricing, and additional information, please don't hesitate to contact us. Gaea Rock is committed to meeting your drilling needs with excellence.

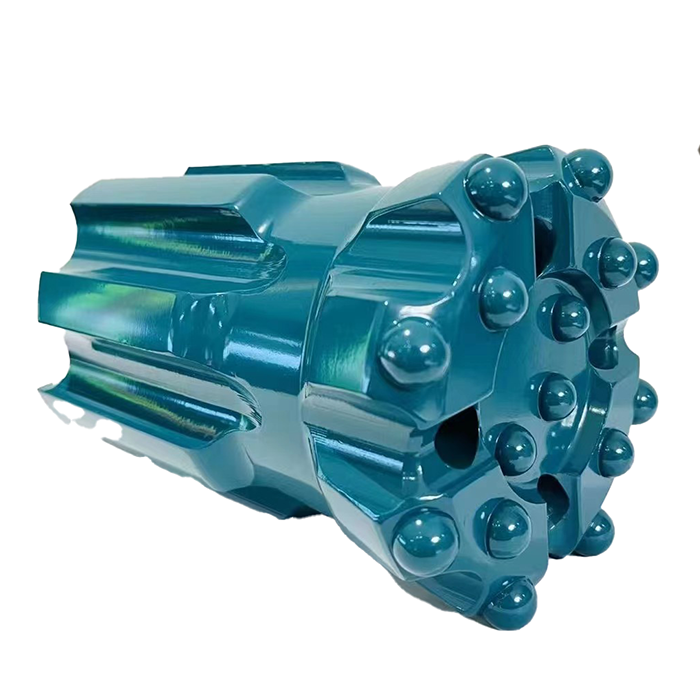

The passivation service life of ball tooth series drill bits is long, and its non-grinding life is about 5-6 times the grinding life of the drill bit with the same diameter blade, which is beneficial to saving auxiliary man-hours, reducing workers' physical labor and speeding up the project. Therefore, taper connection and threaded connection ball bits of different diameters are widely used in various types of hard and brittle rocks to cooperate with drilling rigs for rock drilling. Swedish engineering and technical personnel believe that the combination of ball-tooth drill bits and hydraulic rock drilling rigs is the best match for modern rock drilling technology. In the past 20 years, ball tooth series bits have developed rapidly at home and abroad. It has been realized with the goal of saving drilling auxiliary man-hours and increasing industrial drilling speed by quickly drilling holes with hydraulic rock drills.

Compared with traditional blade drill bits, column-tooth drill bits have the characteristics of longer grinding cycle and faster drilling speed. They are mainly divided into the following categories:

1. Down-the-hole cylindrical bit. The down-the-hole cylindrical drill bit is a drill bit used in conjunction with the down-the-hole impactor. It cooperates with the impactor to perform drilling operations. It is widely used in open-pit mining, quarries, hydropower projects, and drilling of water wells. , Excavation side pillar support, etc. They are divided into: low-pressure down-the-hole column drill bits, medium and high air pressure down-the-hole column drill bits. Down-the-hole column drill bits are used in conjunction with down-the-hole impactors and have drilling flatness. It has the characteristics of straightness, fast speed and deep hole drilling. Therefore, it has been widely used in recent years.

2. Threaded connection column tooth bit. The threaded connection column tooth is mainly a drill bit used in conjunction with a hydraulic rock drill (or pneumatic rock drill) and a hydraulic drill rod (pneumatic drill rod). It uses different forms of threads to cooperate with the drill rod to perform drilling operations. The diameter of the drill bit is: ¢32-¢203mm, mainly used in underground mining, open-pit mining, blast furnace openings in steel plants, etc. It is fast and easy to grind.

3. Taper connection column tooth bit. The taper connection column tooth drill bit is mainly a drill bit used in conjunction with the pneumatic rock drill and the taper rod. It is connected with the drill rod through the taper to perform drilling operations. It is mainly used in secondary crushing of mines, anchor support, and tunnels. excavation and other fields. The column tooth drill bits produced by our company are designed according to ISO international standards. Adopt symmetrical structure design. It has good powder discharge effect, strong crushing ability and fast rock drilling speed.