- Gaea

- 中国

- 5-25天

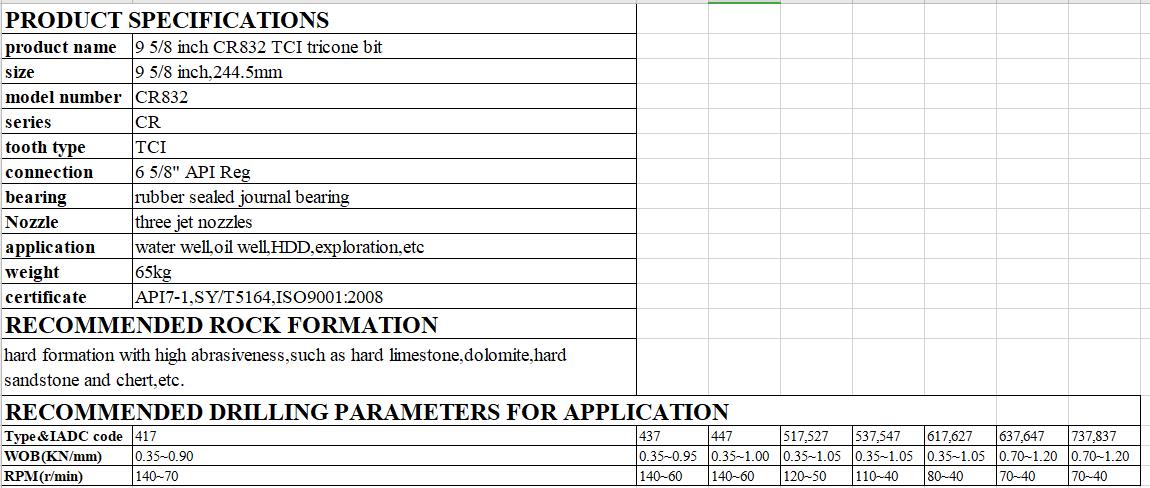

cone drilling bit maximize the use of both conical and chisel tungsten carbide inserts of large diameters and high projection. This cutting structure design, combined with maximum cone offset, results in high bit penetration rates. The deep intermesh of cutter rows prevents bit bailing in sticky formations

Tricone Roller Bits 832

Related Reports:

Correct use of roller cone bits tricone bits;

Types and functions of tricone drill bits;

Structural features and instructions for roller cone bits(tricone bits)

Cone drilling bit is one of Liaoning Gaea's professional products, they are widely used in the oil and gas industry for drilling operations in hard rock formations. Our cone drilling bit are engineered with premium tungsten carbide inserts for superior wear and durability.

Cone drilling bit maximize the use of both conical and chisel tungsten carbide inserts of large diameters and high projection. This cutting structure design, combined with maximum cone offset, results in high bit penetration rates. The deep intermesh of cutter rows prevents bit bailing in sticky formations.

Cone drilling bit are a type of drill bit commonly used in the oil and gas industry for drilling through hard rock formations. They are designed with tungsten carbide inserts on the cutting surface to provide high durability and resistance against wear.

Cone drilling bit are known for their excellent drilling performance in challenging formations such as hard limestone, dolomite, shale, and abrasive sandstone. The tungsten carbide inserts are strategically placed on the bit's cutting structure to enhance the cutting efficiency and prolong the bit's lifespan.

These bits are available in various designs and configurations to suit different drilling applications and formations. They can be used for both rotary drilling and percussion drilling methods, depending on the specific requirements of the project.

Cone drilling bit are highly regarded for their ability to deliver efficient drilling rates, improved ROP (Rate of Penetration), and extended bit life. They are widely used in oil and gas exploration, geothermal drilling, mining, and other industries that require drilling through hard rock formations.

It's important to note that the selection of the appropriate Cone drilling bit depends on factors such as the formation type, drilling parameters, and specific project requirements. Consulting with drilling experts and considering the recommendations of the bit manufacturers is crucial to ensure the most suitable TCI bit is chosen for the job.

Our company has rich experience and expertise in the field of Cone drilling bit, our engineer team is proficient in this and can provide customers with tailor-made solutions according to specific needs. We continuously improve product quality and performance through continuous R&D and innovation to ensure our Cone drilling bit perform well in various challenging environments.