- Gaea

- China

- 10 days

- 3000pcs/month

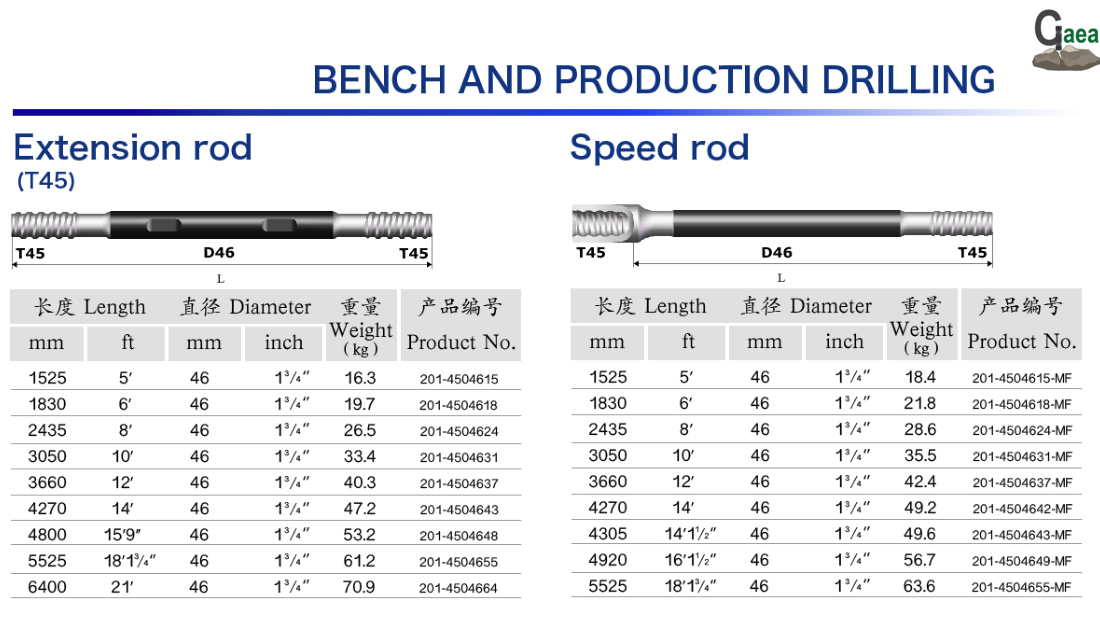

Liaoning Gaea Rock Split Machinery Technology Co.,Ltd is a manufacturer which have rich experience in rock splitting technical and export quarrying and drilling tools to all over the world.We provide scheme design,device manufacture and drilling tools sell. We devote to research,scheme design, products manufacture and sell the steady, trustable and cost-efficient rock splitting system solutions.T45 extension rod including:3050 3660 4300 4915 5525mm

T45 rock extension rod drill pipe drill rod MF MM rock drilling tools

Related reports:

How to store and use mining drill pipes are all things we should master;

Manufacturing process of threaded drill rod;

Geological drill pipe manufacturer Gaea Technology explains the use of drill pipe biTts;

T45 extension rods introduction :

Welcome to Liaoning Gaea, a leading provider of high-quality T45 extension rods for various industries. Our T45 extension rods are designed to meet the demanding needs of mining, railway, highway, water engineering, coal mining, metal mining, quarrying, and tunneling projects. With our extensive expertise and commitment to excellence, we ensure that our T45 extension rods deliver exceptional performance and durability in the most challenging environments.

Key Features:

T45 Thread Type: Our T45 extension rods feature a T45 thread type, which is widely recognized in the industry for its reliability and compatibility. This thread type ensures a secure and efficient connection, enabling seamless integration with drilling systems.

Exceptional Durability: The T45 extension rods are manufactured using high-quality materials and advanced manufacturing techniques, ensuring exceptional durability and longevity. These rods can withstand rigorous drilling operations and maintain their structural integrity even in demanding conditions.

Versatile Applications: The T45 extension rods find extensive applications in various industries. Let's explore some of the key areas where these rods excel:

Mining: T45 extension rods are widely used in mining operations, where they provide reliable support for drilling and exploration activities. Their robust construction and compatibility with drilling systems make them an ideal choice for mining professionals.

Railway and Highway Construction: In railway and highway construction projects, T45 extension rods play a crucial role in drilling holes for foundations, tunnels, and other structural components. They ensure precise and efficient drilling, contributing to the overall construction efficiency.

Water Engineering: T45 extension rods are employed in water engineering projects for drilling wells, boreholes, and geotechnical investigations. Their compatibility with different drilling systems allows for seamless integration and effective water resource management.

Coal Mining: The T45 extension rods are well-suited for coal mining applications, where they facilitate the extraction of coal and other minerals. Their robust design and resistance to wear make them reliable tools for underground mining operations.

Metal Mining: T45 extension rods are commonly utilized in metal mining operations for exploration and extraction purposes. Their high-performance characteristics enable efficient drilling in challenging geological conditions.

Quarrying and Stone Cutting: T45 extension rods are essential tools in quarrying and stone cutting industries. They enable precise drilling for extracting stone blocks, contributing to the production of high-quality materials for construction and decorative purposes.

Tunneling Projects: T45 extension rods find extensive use in tunneling projects, including the construction of underground tunnels for transportation systems, utilities, and infrastructure. Their reliability and compatibility make them indispensable for tunneling professionals.

Conclusion:

At Liaoning Gaea, we take pride in offering top-of-the-line T45 extension rods that meet the diverse needs of the mining, railway, highway, water engineering, coal mining, metal mining, quarrying, and tunneling industries. Our T45 extension rods deliver exceptional performance, durability, and compatibility with various drilling systems. Trust in our expertise and experience to provide you with the reliable tools you need for your critical projects. Contact us today to learn more about our T45 extension rods and how they can enhance your operations.

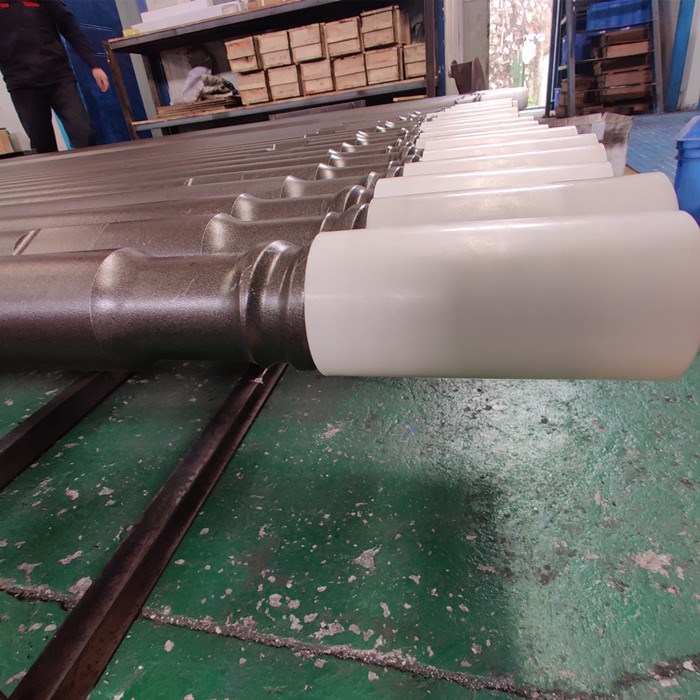

Underground mining drill pipe is one of the important tools in the production process of geological exploration and coal exploration. The downhole mining drill pipe adopts high-quality, high-efficiency, energy-saving, and pollution-free friction welding technology, and the post-weld heat treatment process is studied, and a toughened overall geological drill pipe(extension rod) is obtained.

Welded joint

The comprehensive mechanical performance of the DZ60 geological drilling rig is higher than the value specified in the technical standard for bars and pipes of the DZ60 geological drilling rig.

The role of underground mining drill pipe(extension rod):

Down-hole mining drill pipe is used to connect the ground equipment of the drilling rig and the drilling and grinding equipment or bottom hole equipment at the bottom of the well.The purpose of the drill pipe(extension rod) is to transport the drilling mud to the drill bit(thread button bits) and raise, lower or rotate the bottom hole drilling tool. The drill pipe must be able to withstand huge internal and external pressures, twisting forces, bending, Flexibility and vibration. In the mining and refining process, the underground mining drill pipe(extension rod) can be reused.

After several processing steps, the original steel pipes and bare pipes are made into underground mining drill pipes. First, through the treatment of the steel pipe thickening step, the outer surface of the smooth pipe is bent inward, and the wall of the steel pipe is thickened. In the next step, the threads will be machined and plated with copper to increase strength.

Then perform non-destructive quality control, and then weld the steel pipe joints. Then, the pipe body will undergo welding heat treatment and welding final treatment to eliminate welding residual pressure. Before painting and packaging the finished underground mining drill pipe, the finished steel pipe should be subjected to some other tests, including

Hardness testing, pressure testing and non-destructive testing.

Features of underground mining drill pipe(extension rod):

1. The drill pipe for underground mining can be cold drawn once to form a blade without annealing, and has good toughness and durability.

2. The underground mining drill pipe(extension rod) of the pile driver equipment is connected by plug-in screws, which is convenient and quick to disassemble, has good sealing performance, high tensile strength and high pile quality. Good verticality, easy to disassemble and install.

This is the specification: